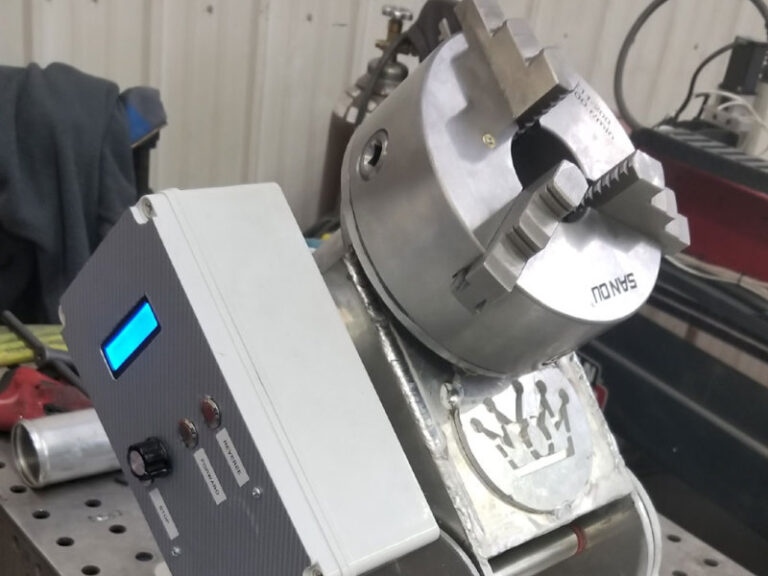

After designing the Arduino welding positioner, I had figured that I have enough experience to tackle a more complicated system.

The PM-727V Milling machine is a manual control system that involves hand cranking the X, Y and Z axis. The Y axis isn’t much of an issue being the travel distance is very little. The X axis.. This involves a lot of cranking and if you desire a precise speed, its near impossible to do this by hand.

The Z axis, this is most important. The Z axis crank location is inconvenient and it takes some muscle to crank the Z axis in the upward position.

My plan was to utilize stepper motors for both X and Z axis. Both axis will provide speed control in all directions, homing switch control and while still allowing availability to still use it as hand crank system.

To operate this machine I am using 2 Arduino Megas paired with momentary push buttons, lcd screen and potentiometers.

This was done to minimize interference of blocking code while driving 2 stepper motors at the same time.

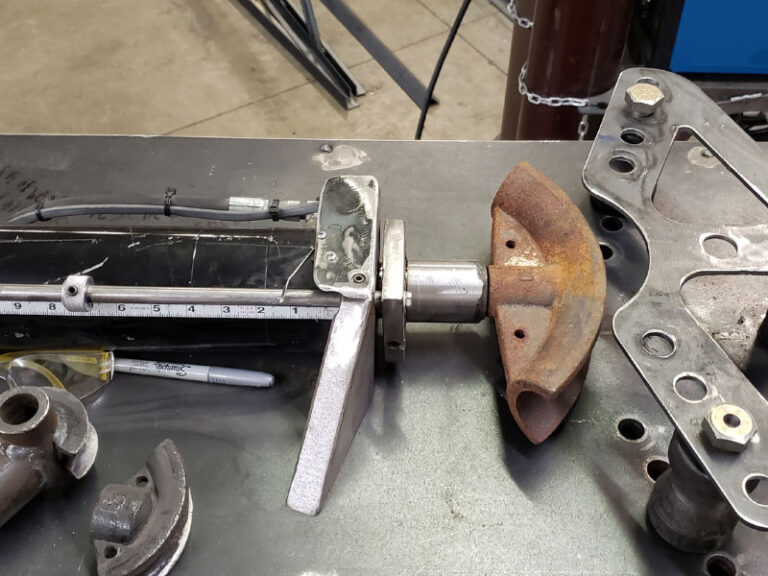

The 3rd Arduino, uno is used to operate a rotary positioner.

The inside of the control box, its a bit of a mess but all this was a process of learning and troubleshooting.