After the Cam Sensor Retrofit I decided that I would gather the parts necessary to Run this engine full sequential. Some of the benefits that interested me in a Sequential ignition setup was:

- Ability to control each cylinder

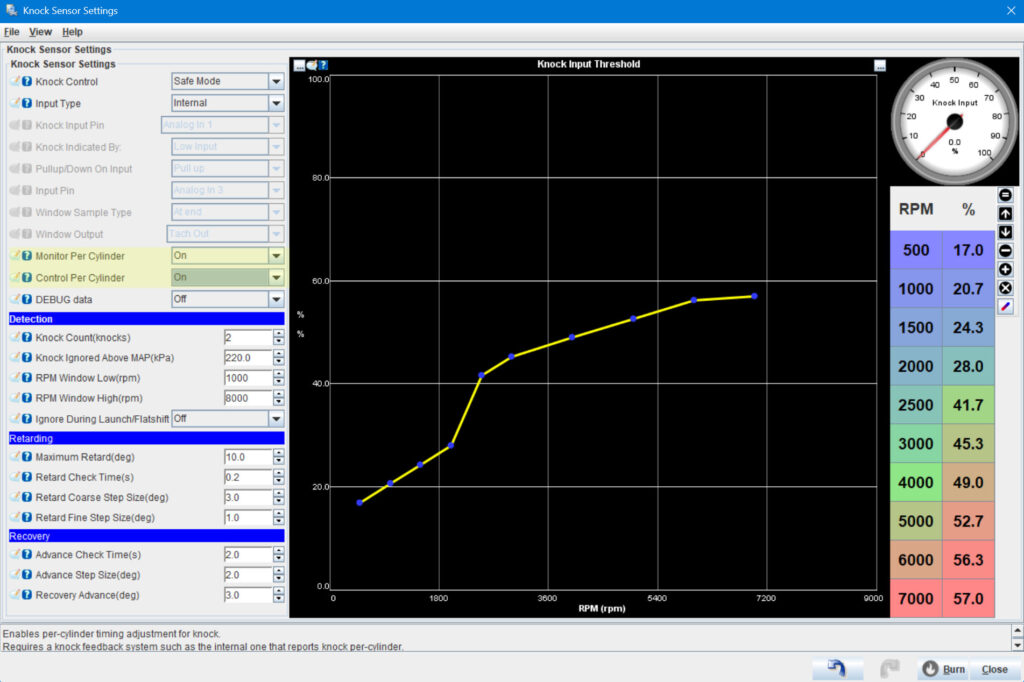

- Knock detection and control of each cylinder

- Shorter ignition wires

- Stronger Spark

Benefits I learned of after getting this setup running:

- Fuel Economy. This is mentioned in every ” batch fire vs sequential ” question raised but is explained as unnecessary or barely worth it. I beg to disagree. Right away after getting my engine running full sequential It was running 10-11.0 AFR rich at Idle where it previously ran 13.5-13.9 at Idle and 2% Duty cycle. To get it to run optimal I had to adjust to fuel map significantly at idle, which net me a 1% duty cycle and rock solid 14.0 AFR which was not achievable on batch mode.

- Idle Control. The closed loop idle is much steadier and more responsive.

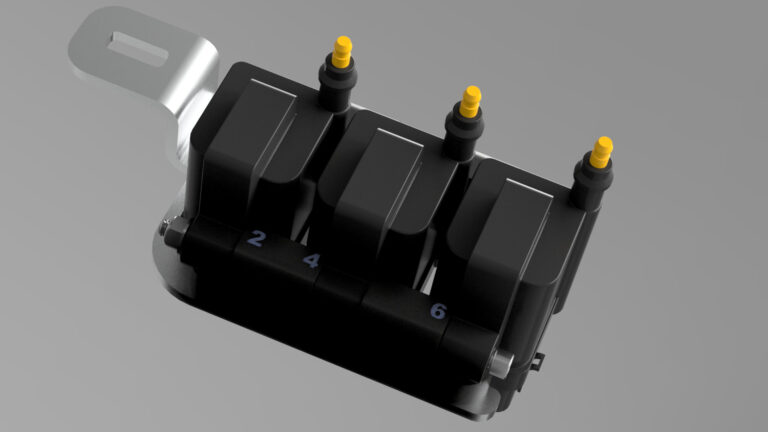

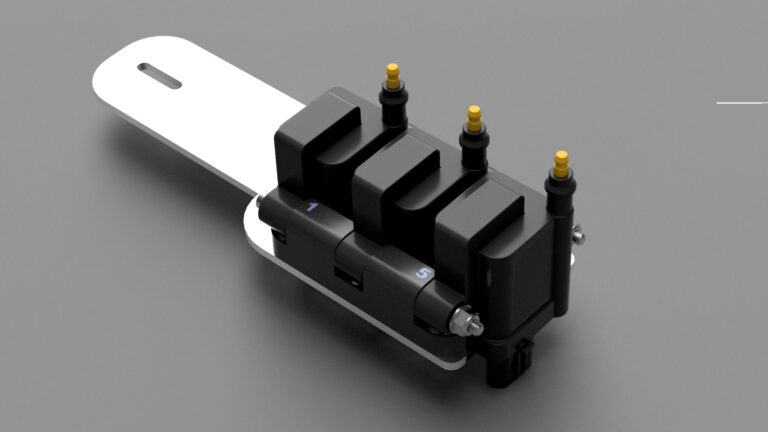

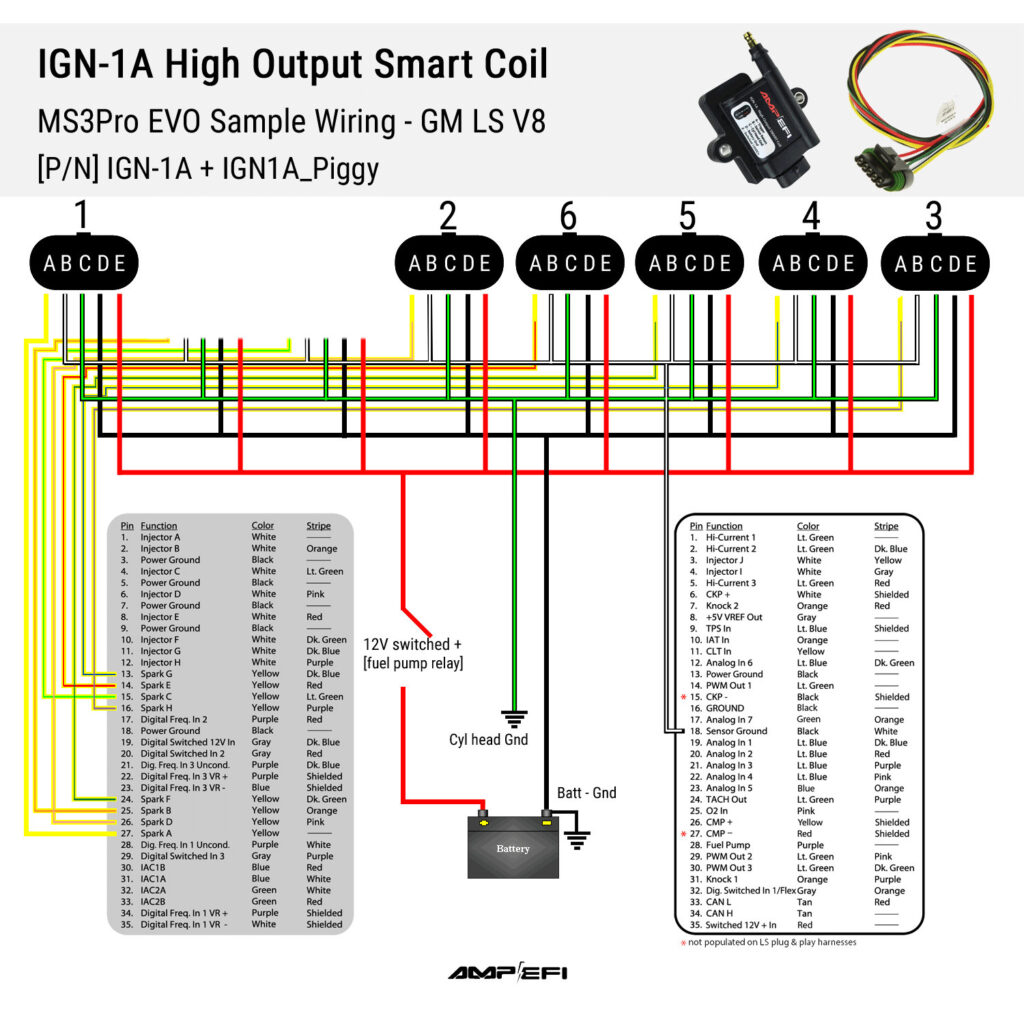

Next was deciding on coils. I really liked the IGN1A coils from AmpEFI. However they were expensive, all together they would be just under $500 for 6 with connectors ( no pigtails). I decided against coil on plug due to the G4 Manifold, to use them would require removing the manifold anytime I needed to access the spark plugs. I also chose not to use dumb coils because they would require another quadspark and would add up to about the cost of the smart coils.

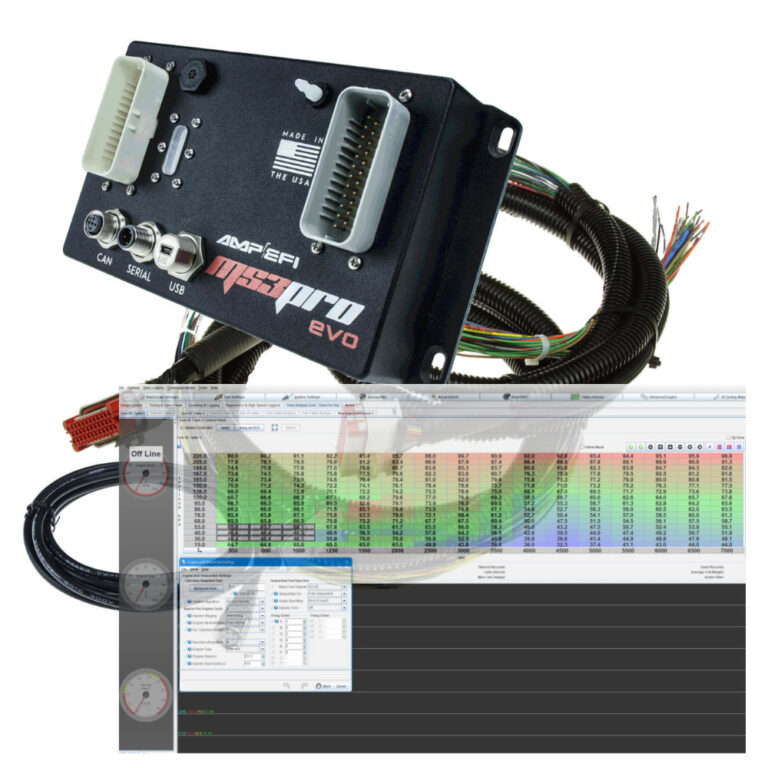

The benefit of the smart coils is they do not need an external trigger and can be controlled directly by the MS3Pro.

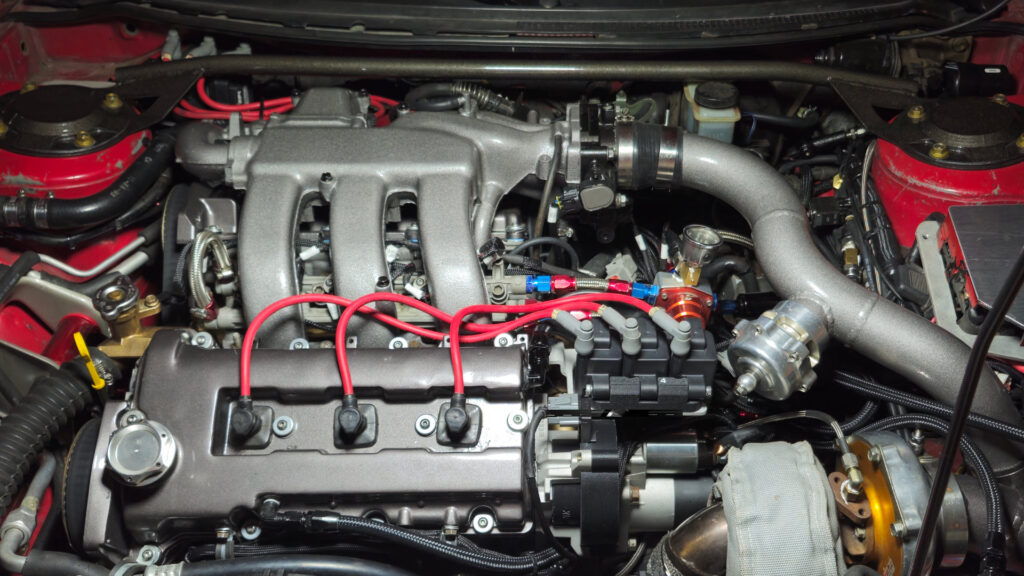

Mounting the coils was very challenging and took quite a lot of designing printing and test fitting. In the end I choose the best places was 3 behind the Cam sensor and 3 behind the rear bank. Mounting all 6 near each other was not possible. This is also allow me to shorten all the spark plug wires drastically.

Many revision’s were made to the final brackets to make them compact and accurate as possible.

If you would like to use this design, I have uploaded the STEP Files to the downloads section. The plastic bits were printed in ABS-GF, the hardware was sourced from McMaster-Carr. All part numbers included in the download. The metal brackets are from 3/16 Aluminum with tapped mounting holes. The sheet metal files are also included and could be utilized thru SendCutSend.

For Wiring I followed these instructions exactly.

For Simplictiy I documented the wires as follows:

A 1 Yellow

B 2 Yellow/orange

C 3 Yellow/green

D 4 Yellow/pink

E 5 Yellow/red

F 6 Yellow/dark-green

For Routing Wires in a Harness:

135

yellow

yellow/light green

yellow/red

246

yellow/orange

yellow/pink

yellow/dark-green

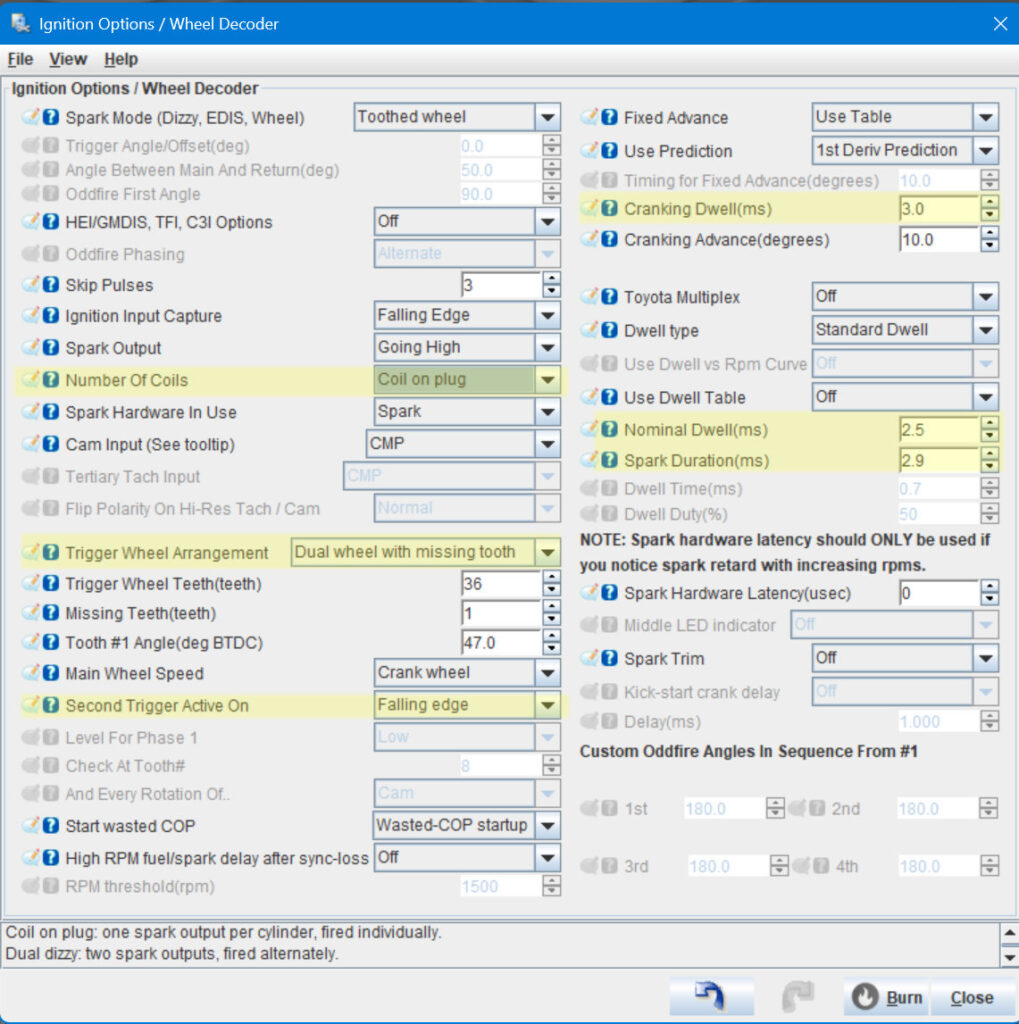

Next The Settings need to be changed in order for this to start in sequential mode, other wise it will continue to think its batch and only fire 3 cylinders.

Change the settings highlighted in yellow to as they are shown.

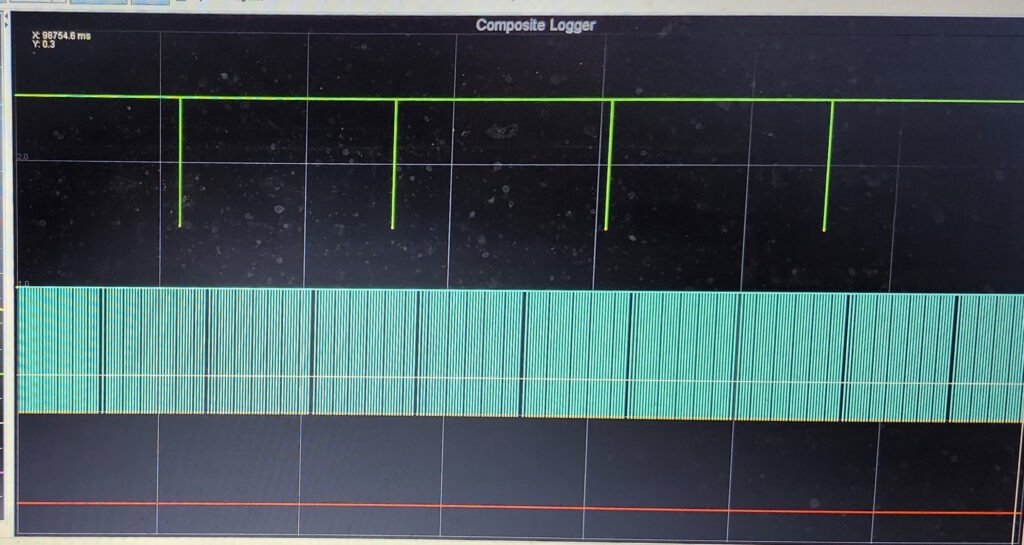

I was having difficulty getting clean cam signal after installing these coils, I got lots of noise causing a Cam fault in Tunerstudio. Part of my process of elimination was adding copper shielding into the Printed Cam Cover cap.

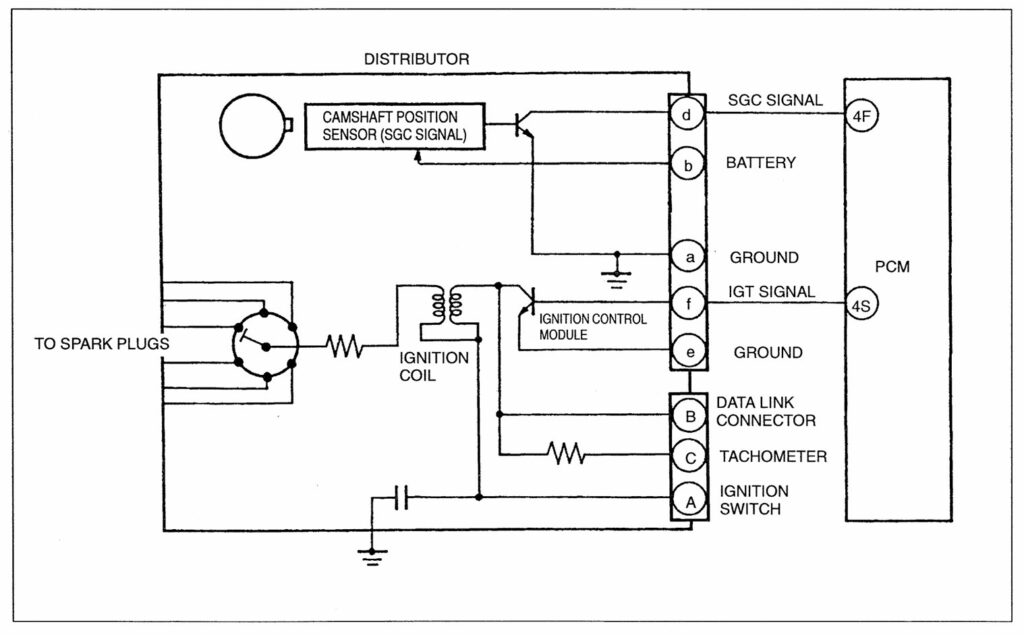

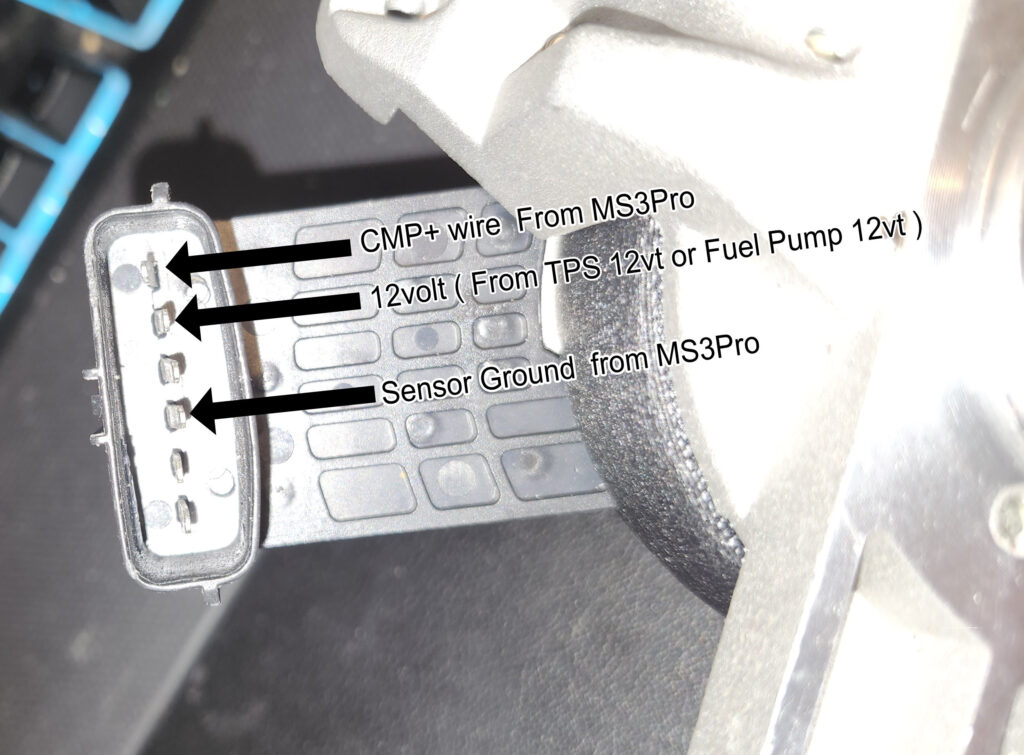

Eventually all my diagnostics of trying different grounding locations, mounting locations and noise filtering lead to no significant changes. Then I realized I connected the 12vt for my Cam sensor to the 12vt powering the coils. I rewired the 12vt for the cam sensor to connect to the 12vt for the TPS and all noise was resolved, and this is the type of CAM signal you can expect with the 95 Disty Cam Sensor.

How useful was this post?

Click on a star to rate it!

Average rating 5 / 5. Vote count: 1

No votes so far! Be the first to rate this post.

We are sorry that this post was not useful for you!

Let us improve this post!

Tell us how we can improve this post?