Transmission Rebuild

Page 9

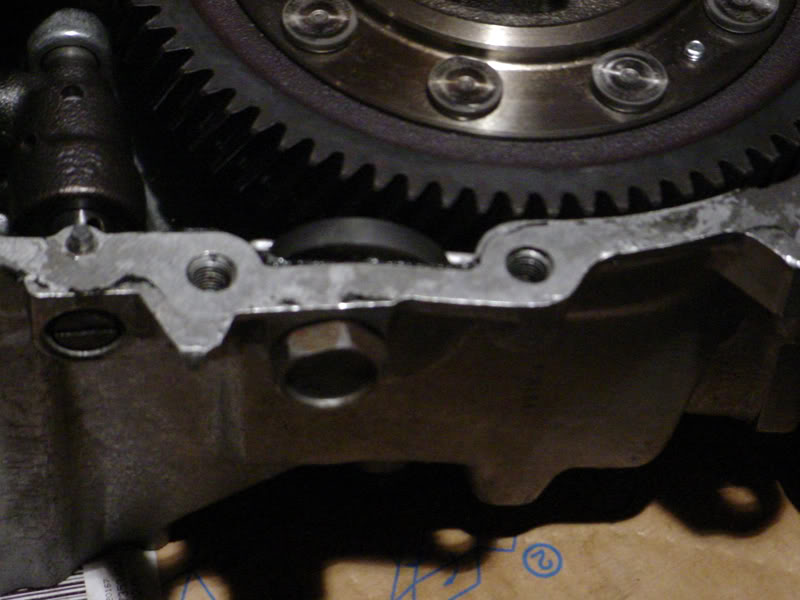

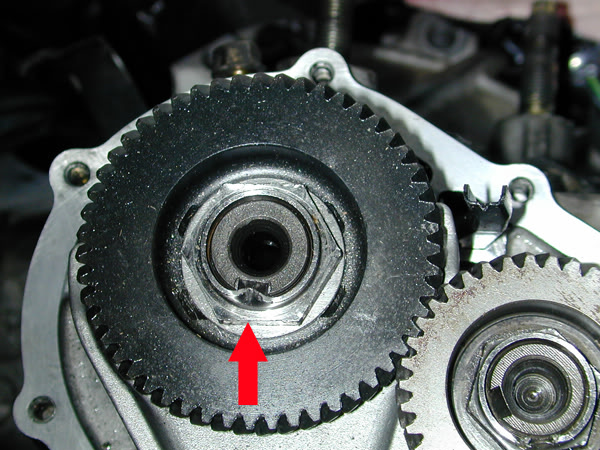

38. Don’t forget to re-install the magnetic drain ring!! Clean it off thoroughly and just drop it in.

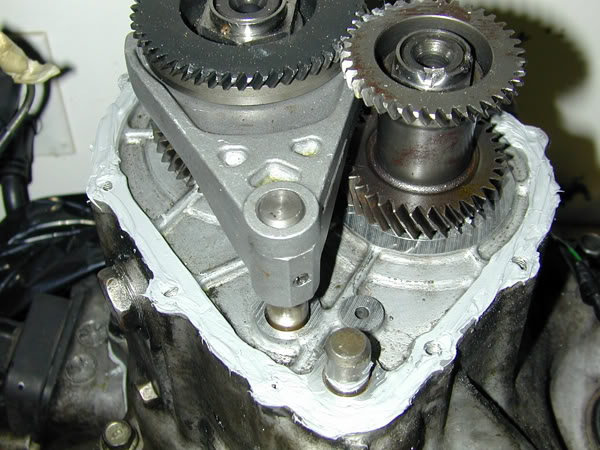

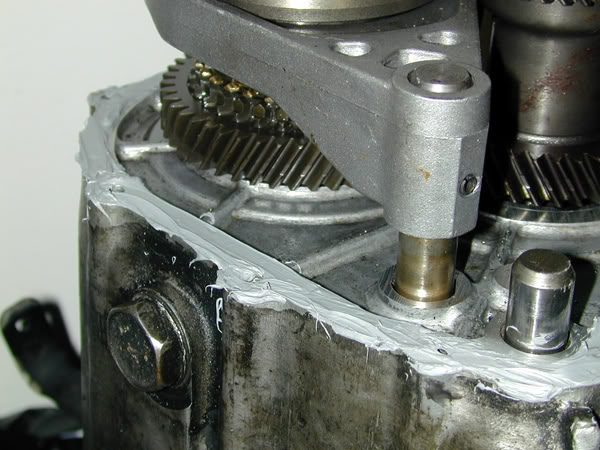

Once it’s all together, you’ll need to fiddle with the shifter (on the outside of the case, where the actual shifter linkage attaches to) and using a screwdriver or similar tool for leverage, shift through the gears ensuring all gears are shifting smooth. You may need to install and remove the outer case a few times, as without the case, the shafts can move around and simulate bad or notchy shifting.

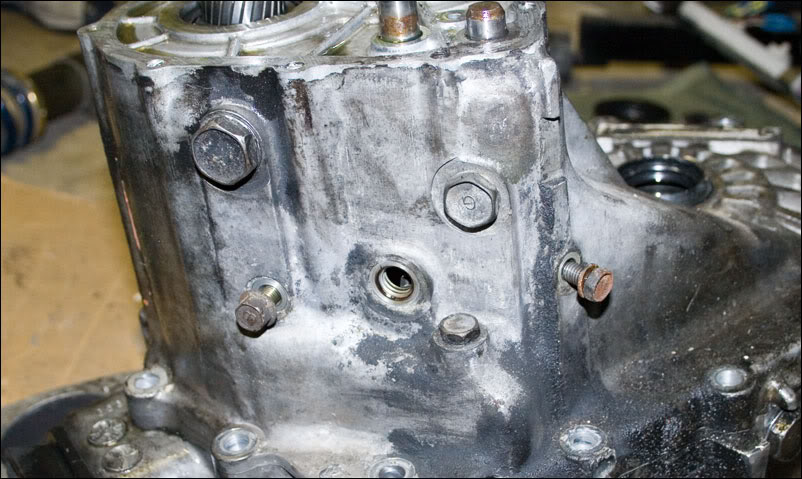

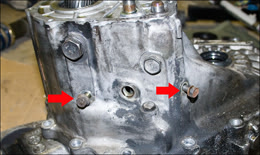

40. With the outer case re-installed, it’s time to thread in the 12mm bolts we removed earlier and thread in all the large 15mm bolts that hold the case together. Don’t forget to re-install the spring and ball into the case for the reverse lever!! [14mm bolt] The ball goes in first, then the spring.

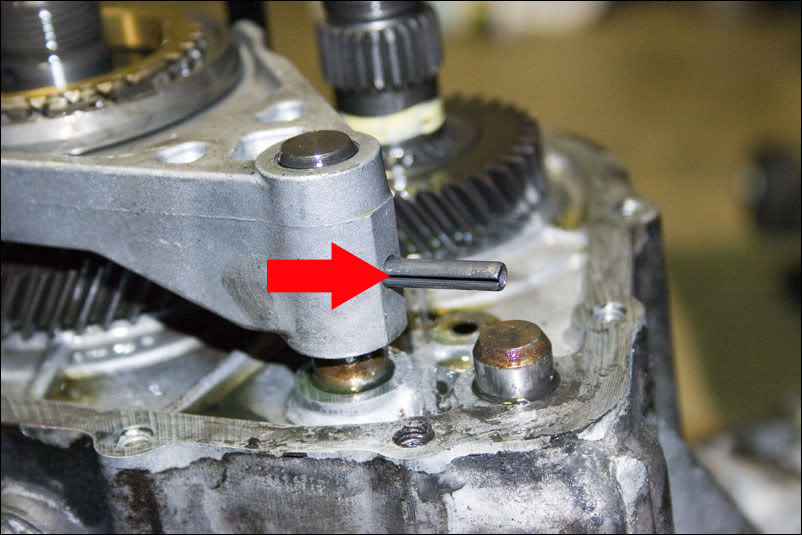

41. Now comes the 5th gear swap part…simply slide the new gears over the shaft and re-install the fork arm and sleeve pin. Pay very close attention to the syncros. It’s very important that they are seated properly. If you look closely, they are notched in such a way, that they only fit in one way….the right way

Notes and Tips

Axles

4cyl Applications [bG and EC chassis]

MX3 GS, MX6, 626, ProbeGT all use the same differential side spline counts on the axles (28)

If using this in a BG or EC chassis, you cannot use the MX6/626 or ProbeGT axles, they are too long, the MX3 GS axles should be used. The hub spline count is the same for the EC and BG chassis cars (26) and Alternatively, you can source a set of KIA Sephia axles from a BP equipped car, as well as the KIA Intermediate Shaft. These are also 28/26 spline counts.

V6 Applications [bG and EC chassis]

Again, must use the MX3 GS or KIA Sephia axles, but can use any Intermediate shaft from the above listed K-series V6 cars. They all share the same 28/26 spline counts.

Gear Ratios

MX3 GS | ProbeGT

Both share the same shorter gearing as the BP 4cyl G-series cars.

MX6 | 626

Both share taller gearing, similar to the F-series trans. These are also the cars to source 5th gear for the swap.

Internals

This info was sourced from this Probetalk thread. As well as info from Gro_Harlem who has done the ZX2 internal parts swap.

For a stronger transmission, look for a 1997+ Ford Escort w/SPI DOHC and the 1998+ Ford ZX2 w/zetec DOHC. These cars also use a G-series trans. The case cannot interchange, neither can the differential, but all the internals can be swapped over. It’s been said the Escort/ZX2 trans weak point is the spider gears in the differential, since you will use your current differential or the MSP LSD, that eliminates the problem. The main reason for this swap, are different gear ratios, stronger gears and syncros.

It’s also noted that the Ford Escape used a G-series trans. Unknown as to what years or if it was the FWD and/or AWD models.

Reference Threads:

OEM LSD for G-series Transmissions

WorkLog: 2.5L KL V6 Swap & Race Build Up [bG Chassis]

G-series vs. F-series Visual Comparison

Tips:

Clear a large area on your workbench or floor. Spread out some cardboard and lay down some shop towels. It’ll help to have a large area to set down the parts, especially if you cannot walk around the workbench and have to move the transmission around alot.

It really helps to have a friend lend a hand.

Plan ahead. Make sure to have all the parts and tools ON HAND and have the bearings pre-pressed on if you do not have a press before starting.

Take your time, the transmission has many intricate parts, don’t force anything or pry on the gears.

Have an FSM or repair manual on hand.

Don’t take apart more than is needed to install the LSD and 5th Gears. Unless you need an overhaul, don’t mess with it.

Lay out all the parts you remove on shop towels neatly and in the order they came out. This not only helps to re-install them later, but keeps the parts clean and free from possible damage. If you leave the parts out for an extended period of time, cover them up with shop towels or plastic garbage bags. Use plastic baggies with labels for the bolts and other hardware.

If you do not have a friend with a hydraulic press, make sure you chose your machine shop carefully and make sure they know 100% the correct placement of the speedo drive gear. Watch them do it!! Don’t take it to Joe Grande!! It’ll save you the headache of buying new parts and getting held up on completing the job.