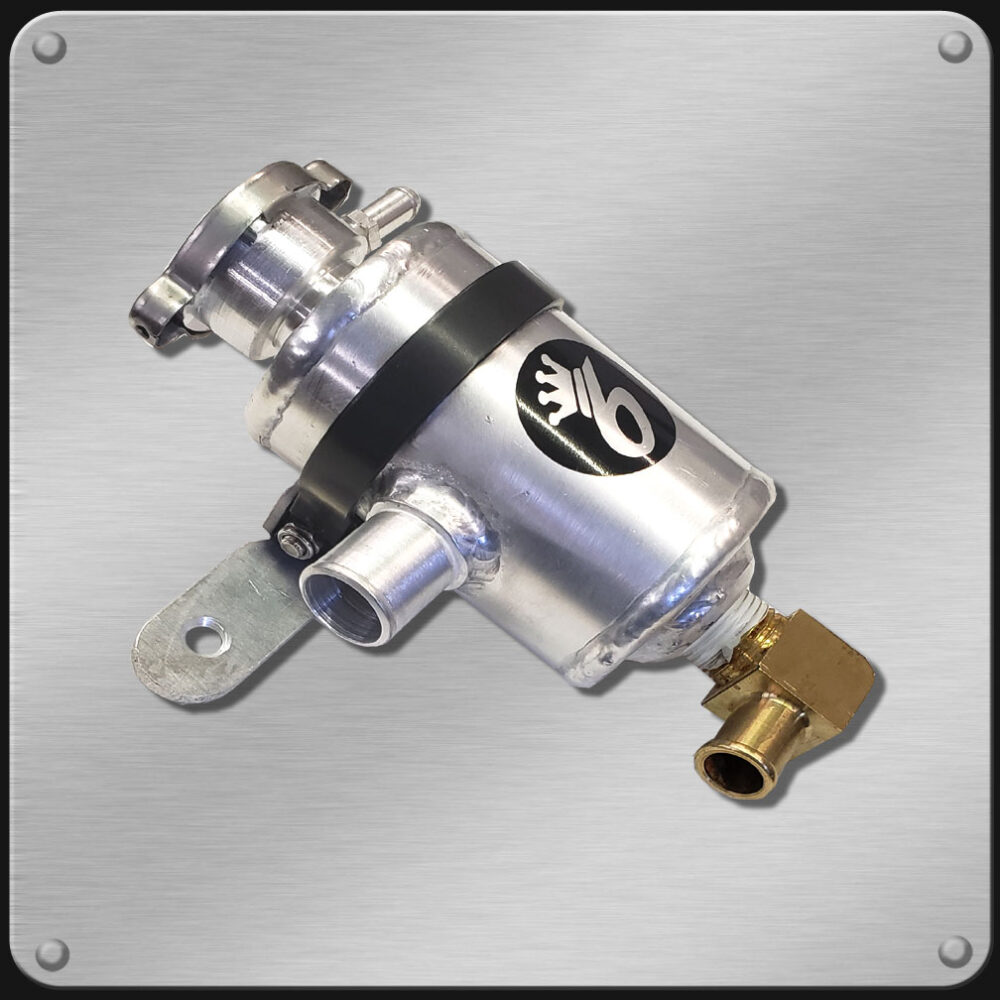

[vc_row][vc_column][vc_column_text]Our V2 Expansion tank is a quality replacement to the plastic OEM expansion tank, Utilizing the same size OEM hoses. Completely TIG welded using 16Ga aluminum tubing with aluminum bungs and cap flange. Each tank is pressure tested, and equipped with a brass 90 degree fitting for the lower hose.

Please note, this tank is designed with a bracket that mounts in the factory position but may require modification to the fan shroud and lower hose.

This Tank is best used with slim fans.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text]Features:[/vc_column_text][vntd_list items=”2.5“ OD x 16GA 5052 Aluminum Tubing,Adjustable Bottom Brass 90″ icon=”fas fa-check”][vc_column_text]Options:

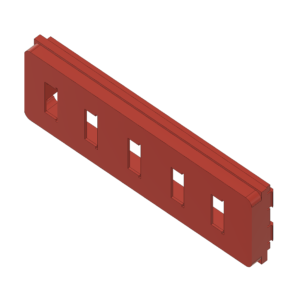

Tank Only – Select this option if you will be printing the bracket yourself. You will receive only the expansion tank.

Tank with Printed Bracket – Select this option for a complete setup. I print these brackets in ASA Filament at 20% Subcubic Infill for maximum strength.[/vc_column_text][vc_column_text]The 3d Printed Bracket:

This slide in bracket aids in easy fitting and requires no additional fasteners. Simply slide the V3 Tank into the bracket and the weight of the hoses will keep it from popping out. [/vc_column_text][/vc_column][vc_column width=”1/2″][vc_single_image image=”6268″ title=”V2 vs OEM Comparison”][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text]Free 3D File

Do you have a 3D Printer?

If you already are capable of printing high temp materials, We supply the 3D STL file for this tank at no extra charge.

→Select the 3d Printing Guide Tab for more information and download file.

Benefits:[/vc_column_text][vntd_icon_list icons_color=”accent” elements=”%5B%7B%22icon_fontawesome%22%3A%22fas%20fa-hammer%22%2C%22text%22%3A%22If%20your%20bracket%20becomes%20damaged%2C%20you%20can%20print%20another.%22%7D%2C%7B%22icon_fontawesome%22%3A%22fas%20fa-tools%22%2C%22text%22%3A%22Modify%20the%20bracket%20to%20fit%20your%20needs.%22%7D%2C%7B%22icon_fontawesome%22%3A%22fas%20fa-layer-group%22%2C%22text%22%3A%22Print%20with%20more%20infill%20for%20a%20stronger%20bracket.%22%7D%5D”][/vc_column][vc_column width=”1/2″][vc_column_text][woo3dviewer model_url=”//www.king6fab.com/wp-content/uploads/2022/10/V2-SwirlTank-v4.stl” material_url=”” thumbnail_url=”” canvas_width=”500″ canvas_height=”500″ canvas_border=”true” display_mode=”3d_model” display_mode_mobile=”3d_model” rendered_file_url=”” model_color=”#dd8808″ background_color=”#000000″ background_transparency=”false” model_transparency=”opaque” model_shininess=”plastic” show_grid=”true” grid_color=”#9b9b9b” show_ground=”true” ground_color=”#000000″ show_shadow=”false” show_mirror=”false” auto_rotation=”false” rotation_x=”0″ rotation_y=”0″ rotation_z=”0″ offset_z=”7.105427357601002e-15″ light_source1=”false” light_source2=”true” light_source3=”false” light_source4=”false” light_source5=”false” light_source6=”true” light_source7=”false” light_source8=”false” light_source9=”false” remember_camera_position=”true” show_controls=”false” camera_position_x=”-212.58181046573148″ camera_position_y=”90.79613130040318″ camera_position_z=”-39.16949221270209″ camera_lookat_x=”0.9067056937771698″ camera_lookat_y=”-0.38726440913572907″ camera_lookat_z=”0.16706604169853256″ controls_target_x=”0″ controls_target_y=”0″ controls_target_z=”0″][/vc_column_text][/vc_column][/vc_row]

| Options | Tank Only, Tank With 3D Printed Bracket |

|---|

3D Printing Guide

If the Download Fails, you can also find the file on my Thingiverse Profile Located Here

| 3D STL File Download | V2 Rev4 ClampV2 , Tank Rev4 Base |

| Print Orientation | This model is best printed upside Down. |

| Recommended Material | ASA or ABS |

| Recommended Resolution | .20 or greater |

| Recommended Infill | 15% or greater |

| Recommended Support | Tree |

| Recommended Adhesion | Brim or None |

| Additional Parts Needed | (Qty 4) 5mm -.08 x 12mm Socket Head Screw |

ASA Filament Information

Pros

- Strong UV resistance

- Strong chemical resistance

- Water resistance

- Post-processing capabilities with acetone

- High Impact resistance

- Tough

- Durable

- Good finish

- Anti-static

Cons

- Release dangerous fumes

- Expensive compared to other 3D printing filaments in the market

- Higher extruder temperatures

- High printing energy consumption

- Parts may crack

- Parts may warp and sink