1993-1995 v6 KLDE CEL Codes

The OBD-1 computer system was used in the 93-95 Ford Probe, Mx6 & 626

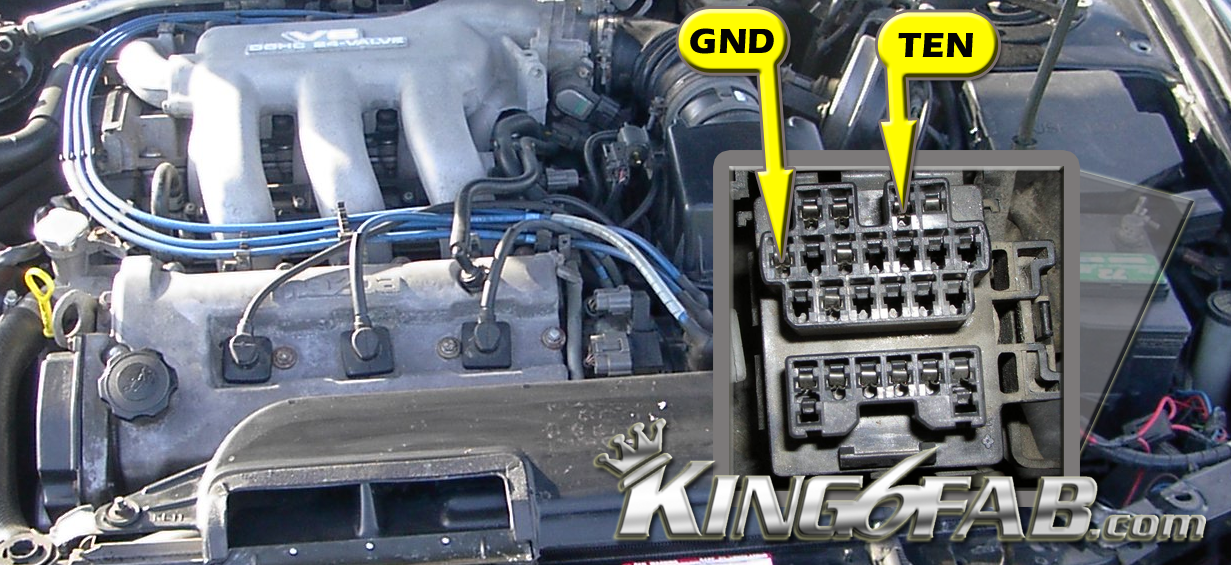

- To check for OBD-1 codes, use a paperclip and insert it into the 10 and ground pins in the diagnostics box under the hood by the battery.

- Make sure the engine is turned off .

- Once the paperclip is inserted, turn the key to the “on” position, but do NOT start it.

- Start to read the codes, quick flashes are single digits, and slightly longer flashes represent 10’s or 100’s (Example: 2 long flashes and 3 short flashes would be code 23)

OBD-1 CEL CODES.

02- crankshaft position (ckp) sensor or circuit

03- camshaft position (cmp) sensor or circuit

04- camshaft/crankshaft position sensor or circuit

05- knock sensor

08- Mass Airflow (maf) sensor or circuit

09- coolant temperature sensor or circuit

10- Intake air temperature sensor (IAT)

11- Intake air temperature (IAT) sensor or circuit

12- Throttle Position sensor (TPS) or circuit

14- Barometric Pressure Sensor

15- Oxygen sensor or circuit

16- EGR valve position sensor or circuit

17- Oxygen sensor (check the fuel and ignition system performance)

23- Rear 02 sensor inactivation error

24- Rear 02 sensor inversion error

25- Fuel Pressure Regulator Control Solenoid or circuit

26- Solenoid valve(purge control) or circuit

28- EGR vaccum solenoid

29- EGR solenoid vent or circuit

34- Idle Air Control(IAC) valve or circuit

41- VRIS #1 solenoid

46- VRIS #2 solenoid

67- Cooling fan relay or circuit

69- ECTF sensor

111- System pass

112,113- Intake Air Temperature(IAT) sensor or circuit

116,117,118- Engine Coolant Temperature(ECT) sensor or circuit

121,122,123- Throttle Position Sensor(TPS) or circuit

157,158,159- Mass Air Flow(MAF) sensor or circuit

172,173,179,181- Heated oxygen sensor(H02S) or circuit

211,212,213- Ignition system

214,244- Camshaft position(CMP) sensor or circuit

327,332,337- EGR function sensor or circuit

411,412- Idle Air Control(IAC) valve or circuit

452- Vehicle Speed Sensor(VSS) or circuit

511,512,513- PCM

519,521- Power Steering Pressure(PSP) switch or circuit

522- Transmission range sensor or circuit

536- Brake On/Off (BOO) switch or circuit

538- Dynamic response test

539- a/c sensor or circuit

554- Pressure regulator solenoid valve or circuit

559- a/c relay or circuit

563- cooling fan relay(high speed) or circuit

564- cooling fan relay(low speed) or circuit

565- Purge control solenoid valve or circuit

571- EGR solenoid valve(vent) or circuit

572- EGR solenoid valve(vaccum) or circuit

998- PCM

Code 2: NE2 Crankshaft Position Sensor Failure

Sensor Purpose:

This sensor sends un-conditioned Hall-effect signals to the PCME that the PCME uses to determine crankshaft angular velocity (RPM). It is typically termed “NE2” or “CKP2”. This sensor is located low on the engine, on the accessory-side near the crankshaft pulley. It is nestled in behind the dipstick tube.

Fault Description:

This code indicates that the crankshaft position sensor is not sending crankshaft velocity information to the PCME or the PCME is unable to make use of the signal it is sending.

PCM Fault Control Moding:

When Code 2 is present, the PCM ignores it and instead relies on NE1 for crankshaft speed data. This sensor is located in the distributor. This is not the preferred condition since the timing belt tends to make the RPM signals erratic, affecting the PCMs ability to accurately measure crankshaft speed. NOTE:1995+ GTs do not have an NE1 sensor and will not run when Code 2 is present.

Memorization:

This code is memorized in the PCME non-volatile memory.

Things To Check When Diagnosing:

Make sure the NE2 connector and PCM connectors are clean and tight. Re-seat if necessary.

Check the resistance of the NE2 sensor. Unplug it and use an ohmmeter to measure the resistance across the two sensor pins which are the DB and DG wires. It should measure between 520 and 580 ohms.

Check for a short between the DB and DG wires and the BK/R wire (ground). If there is a short, the harness has a short.

Code 3: G Crankshaft Position Sensor Failure

Sensor Purpose:

This sensor sends conditioned Hall-effect signals to the PCME from within the distributor that the PCME uses to determine when #1 cylinder comes up on top-dead center (TDC). This sensor information is used to phase the sequential firing of the fuel injectors during normal SFI operation. This sensor is also known as a camshaft position sensor or CID sensor. It is a Hall-effect sensor located on the igniter in the distributor and it “fired” by a single-vane “wheel” that turns as the exhaust camshaft on the left (radiator)-side bank rotates.

Fault Description:

This code indicates that the G crankshaft (or camshaft) position sensor is not sending camshaft positional information to the PCME or the PCME is unable to make use of the signal it is sending.

PCME Fault Control Moding:

When Code 3 is present, the PCME stops firing the fuel injectors in sequential mode and instead fires them in a “batch” mode since the PCME does not have any way to know where TDC on #1 is. This results in a slight loss of power and a lowering of the engine’s fuel economy

Memorization:

This code is memorized in the PCME non-volatile memory.

Things To Check When Diagnosing:

If code 04 is also present, check the condition of the 5-pin connector at the distributor. Check for +12V present at the R/BK wire to ground.

Check the seating of the 5-pin connector. Make sure it is clean and fully seated.

The igniter in the distributor is probably the most likely cause of this code although a bad PCME is not impossible.

Code 4: NE1 Crankshaft Position Sensor Failure

Sensor Purpose:

This sensor sends a secondary conditioned Hall-effect signal to the PCME from within the distributor that the PCME uses to determine crankshaft speed only under certain conditions. This sensor is used when cranking the engine (when crankshaft speeds are too low to ensure a reliable signal from the un-conditioned NE2 sensor), when the TEN (Test ENgine) pin of the DIAGNOSTIC plug is grounded as when doing base timing & idle adjustments and when NE2 fails. It is located inside the distributor. The Hall effect sensor is located on the igniter and is triggered by a 6-vane interrupter wheel that turns as the exhaust camshaft on the left (radiator)-side rotates.

Fault Description:

This code indicates that the NE1 crankshaft position sensor is not sending crank velocity information to the PCME or the PCME is unable to make use of the signal it is sending.

PCME Fault Control Moding:

When Code 4 is present, the PCME is unable to get crankshaft speed data during cranking and will not start. “Bump” (i.e. push) starting may prove fruitful. Once running, the engine may display no signs of malfunction.

Memorization:

This code is memorized in the PCME non-volatile memory.

Things To Check When Diagnosing:

If code 03 is also present, check the condition of the 5-pin connector at the distributor. Check for +12V present at the R/BK wire to ground.

Check the seating of the 5-pin connector. Make sure it is clean and fully seated.

The igniter in the distributor is probably the most likely cause of this code although a bad PCME is not impossible.

Code 5: Knock Sensor

Sensor Purpose:

This sensor, essentially a microphone, informs the PCME of pinging or detonation occurring within the engine combustion chambers. The sensor is biased to a DC voltage 2.5V by the PCME. It is located under the intake manifold on the KL 2.5L V6. When spark-knock is occurring, this “microphone” oscillates above and below this 2.5V bias by a few tens or hundreds of millivolts. The PCME reads this oscillation and determines from the magnitude of the oscillation how much knocking is occurring and it applies a retard to the ignition timing in an effort to stop the knock – which can be damaging if left unchecked.

Fault Description:

This code indicates that the voltage on the knock sensor A/D channel is above 3.75V or below 1.25V. No other checking is done.

PCME Fault Control Moding:

When Code 5 is present, the PCME is unable to know if knock is occurring. in the interest of engine longevity, an alternate main timing table is referenced that uses highly-reduced advance under high-load (low RPM/high airflow) conditions. The result is a moderate reduction in output power and a not-so-fun-to-drive Probe GT.

Memorization:

This code is memorized in the PCME non-volatile memory.

Things To Check When Diagnosing:

Check all connectors for cleanliness and tightness. Make sure no wiring has been pinched during recent engine servicing. The knock sensor is located under the intake manifold between the cylinder banks and the wiring can easily be damaged by ham-fisted mechanix.

Check for a connection between the sensor connector and the PCME.

Try a known-good knock sensor. If the condition persists, the PCME is probably bad.

Code 8: Volume Airflow Sensor

Sensor Purpose:

This sensor tells the PCME how much air is entering the engine. Located in the intake tract, it uses a sliding-core that changes position based on changes in airflow. The VAF also contains the intake air temperature sensor (IAT) sensor.

Fault Description:

This code indicates that the voltage on the VAF sensor A/D channel is less than 0.200V. There is no upper limit to the VAF reading although it will never be higher than the +5 volt reference from the PCME. Normal VAF voltages range from 4.00V at engine-off, 3.20V at warm idle, 1.80V at moderate acceleration and 0.35V at the absolute maximum core displacement.

The VAF has a 5-position connector:

Wire Color Purpose

R VAF sensor output

P +5V reference from PCME

BK/DB VAF sensor ground

BK/DB IAT sensor ground

BK/R IAT sensor output

PCME Fault Control Moding:

When Code 8 is present, the PCME uses the TPS voltage and idle-switch to determine the “basic” fuel injection amount. There are 3 basic conditions:

Idle switch ON meaning the throttle is closed.

Small throttle angles indicating light load and small airflow amounts.

Large throttle angles indicating heavy load and larger airflows.

In these conditions, 3 different airflow readings are “constructed” and substituted for the ailing VAF sensor’s reading. The result will be a Probe that will run but which will be very ill tempered.

Memorization:

This code is memorized in the PCME non-volatile memory.

Things To Check When Diagnosing:

Check to make sure the connector is tight and clean.

Check for the +5 volt reference from the PCME if EGR and TPS codes are also present.

Check the condition of all grounds.

Make sure the core is not stuck and that the VAF is mounted as close to the horizontal as possible.

The VAF itself is not cheap (>$1000CDN) new so if you suspect it’s bad, do your best to source one from a wrecking yard (don’t tell them how much Ford/Mazda wants for it).

Code 9: Engine Coolant Temperature Sensor

Sensor Purpose:

This sensor tells the PCME the temperature of the coolant in the engine. The sensor is located on the left (radiator-side) cylinder head near the accessory drives. It has a two-wire connector on it. It should not be confused with another temperature sensor located very close it that has only one wire on it – this is the sender for the instrument cluster temperature gauge.

Fault Description:

This code indicates that the voltage on the CTS is lower than 0.195V (indicating a short circuit to ground) or the reading is over 4.883V indicating the connection from the PCME to the sensor is open. The sensor can be checked with an ohmmeter and should fall within the ranges shown in the table:

Coolant/Sensor Temperature Reading in Ohms Typical Voltage Seen

20oC (68oF)

2200 to 2700

2.38V

80oC (176oF)

290 to 350

530mV

91oC (196oF)

226 to 241

390mV

97oC (207oF)

193 to 205

343mV

108oC (226oF)

145 to 153

258mV

110oC (230oF)

137 to 146

249mV

PCME Fault Control Moding:

When Code 9 is present, the PCME substitutes fixed calibration values for the various representations of engine coolant temperature used internally. The engine may idle roughly and may be hard to start. Timing and fuel delivery calculations will be skewed somewhat since the coolant temperature will be only an approximation. As well, to safeguard against overheating, the PCME will also activate the cooling fan constantly.

Memorization:

This code is memorized in the PCME non-volatile memory.

Things To Check When Diagnosing:

Use the above table to check the coolant sensor itself. It is probably the cause of the problem

As always, check the connector to make sure there’s no corrosion or grease or dirt in it.

Disconnect the sensor and check the R/DG wire for +5V with the ignition on. If it is absent, check the wiring to the PCME and the PCME itself.

Code 10: Intake Air Temperature Sensor

Sensor Purpose:

This sensor tells the PCME the temperature of the air entering the engine. This information is used to adjust the amount of fuel delivered and is also used to adjust the amount of spark timing. The IAT sensor is located embedded inside the Volume Airflow Sensor housing and is not itself replaceable although a substitute part may be used (see below) since if the IAT goes, it amounts to replacing a $1000CDN part for a $0.39 thermistor. The fix may not be pretty but it’s cheap. However, the IAT is a robust part and is not likely to fail – ever.

Fault Description:

This code indicates that the voltage on the IAT A/D channel is lower than 0.136V (indicating a short circuit to ground) or the reading is over 4.844V indicating the connection from the PCME to the sensor is open. The sensor can be checked with an ohmmeter and should fall within the ranges shown in the table:

IAT Sensor/Intake Air Temperature Reading in Ohms

-20oC (-4oF)

10000 to 20000

20oC (68oF)

2000 to 3000

60oC (140oF)

400 to 700

PCME Fault Control Moding:

When Code 10 is present, the PCME substitutes fixed calibration values for the various representations of intake air temperature used internally. The engine may idle roughly and may be hard to start. Timing and fuel delivery calculations will be skewed somewhat since the air temperature will be only an approximation.

Memorization:

This code is memorized in the PCME non-volatile memory.

Things To Check When Diagnosing:

Use the above table to check the intake sensor itself. It is probably the cause of the problem

As always, check the connector to make sure there’s no corrosion or grease or dirt in it.

Disconnect the sensor harness at the VAF (go there to see what each pin is for) and check the BK/R wire for +5V with the ignition on. If it is absent, check the wiring to the PCME and the PCME itself.

If the sensor itself is bad, don’t despair. Contact Digi-Key and order up an NTC (Negative Temperature Coefficient) thermistor part number KC017N-ND. This thermistor has a similar characteristic to the OEM part in the VAF near ambient temperatures though it does veer off the OEM characteristic once temperatures begin to get high or low. The car will run quite acceptably with this thermister as a VAF but you might find it runs rich when cold (like below freezing cold). The other problem is that because the thermister reads abnormally high on the “hot” side, the PCM might perceive that the air is hotter than it really is, causing slightly lean conditions during throttle transitions and more importantly, it might start removing spark timing. You decide… I eventually re-calibrated my PCM to use the new sensor since I run it with my MAF setup. Clearly, this is not an option to the average Prober.

It is up to you to mount this device and splice it into the IAT wiring. On my MAF conversion, the VAF (and therefore the IAT) was removed from the car completely. I went to a wrecking yard and found the MAT (Manifold Air Temperature Sensor) from a 1988 Cavalier Z24, removed the sensing element and soldered in the Digi-Key part above. I then mounted this in the Hotshot cold-air tube and spliced the harness into the Probe’s IAT wiring. This is not hard to do and will save you a bundle.

The other, better IMHO, solution is to purchase the engine coolant temperature (ECT) sensor for a GT Probe and use that as your IAT. It has virtually the same characteristic as the in-VAF unit of the GT. The problems with this one is that (a) you’ll need to get the connector for the ECT from a wrecked PGT to use it and (b) the body of the ECT is brass so it may pick up ambient temperatures (e.g. the temp of the Hotshot tube instead of the air passing through it.) Still, to me, this is easily the preferable solution to the Digi-Key part.

Code 12: Throttle Position Sensor

Sensor Purpose:

This sensor tells the PCME the position of the throttle plate. This input is used to determine engine load (in conjunction with BARO, VAF, IAT etc). It also serves to indicate when the throttle is closed via the idle switch. The TPS is located on the throttle body on the “radiator-side” of the engine and has a 4-position electrical connector on it.

The connector wiring is as follows:

Wire Color Purpose

P +5V reference from PCME

Y TPS position signal to PCME

BR TPS idle switch

BK/DB sensor ground

Fault Description:

This code indicates that the voltage on the TPS A/D channel is lower than 0.097V (indicating a short circuit to ground) or the reading is over 4.766V indicating the sensor may be shorted internally. No checking is done of the idle switch so it may malfunction and not set a Code 12. Symptoms of a bad TPS sensor include stumbles or hesitations to throttle inputs, unsteady “cruising” etc. An idle switch misadjustment may cause odd idle behavior.

PCME Fault Control Moding:

When Code 12 is present, the PCME substitutes a calibration value that indicates the throttle is wide-open.

Memorization:

This code is memorized in the PCME non-volatile memory.

Things To Check When Diagnosing:

As always, check the connector to make sure there’s no corrosion or grease or dirt in it.

Disconnect the sensor harness at the TPS and check the P wire for +5V with the ignition on. If it is absent, check the wiring to the PCME and the PCME itself.

Measure the voltage at theY wire while slowly opening the throttle by hand (engine off). It should start at closed throttle at about 0.8V and increase smoothly throughout the range of throttle movement. Look for jumps or dropouts in the voltage as the throttle is opened. If any are found, the TPS is bad.

TPS Adjustment:

Ground the TEN pin in the DIAGNOSTIC box and start the engine. Turn off all loads (A/C, rear defogger, blower etc). Make sure the engine is hot.

If necessary, adjust the throttle stop screw so that the idle reads 650 +/- 25RPM.

Shut off the engine.

Turn on the ignition and check the voltage at the Y wire. If necessary, adjust the TPS sensor to get about 0.8V. This is the “gross” TPS adjustment. Turn off the ignition.

Disconnect the TPS harness. Use an ohmmeter or testlight and measure the continuity between the BR and BK/DB pins on the sensor. Place a 0.006″ feeler gauge between the thottle arm and the stop screw.

If necessary, rotate the sensor until continuity is seen on the switch. Once seen, tighten the sensor back down.

Insert a 0.020″ gauge in place of the 0.006″ unit and check there is no continuity on the idle switch. If there is, go back to step 5 and repeat the adjustment.

Re-connect the harness and once again check the TPS voltage at the Y wire. Make sure it falls in the range from 0.2V to 1.1V. If it does, you’re done. If not, re-start the adjustment procedure.

Code 14: Barometric Pressure Sensor

Sensor Purpose:

This sensor is located within the PCME itself and is used to measure the ambient barometric pressure. The readings are used for VAF corrections, EGR and other calculations.

Fault Description:

This code indicates that the voltage on the baro sensor A/D channel is above 4.49V or below 1.36V. For reference, the “normal” voltage seen at about 100kPa is around 3.80V.

PCME Fault Control Moding:

When Code 14 is present, the PCME substitutes a value of 4.00V for the BARO voltage, which corresponds to something about 101.5kPa. There will probably not be a really noticeable effect on driveability except when at high altitudes (i.e. where the barometric pressure is much less than 101.5kPa).

Memorization:

This code is memorized in the PCME non-volatile memory.

Things To Check When Diagnosing:

Since this sensor is located within the PCME, there’s not much to try except a new PCME.

Codes 15 & 17: LHO2S Inactivation and/or Inversion

Sensor Purpose:

The oxygen sensors are located in the downpipes in the exhaust manifolds. There are two sensors, one on each bank (California cars may use additional sensors). The radiator-side of the engine is known as the “left” side and codes 15 and 17 apply to it. The firewall side of the engine is known as the “right” side and codes 23 and 24 apply to it.

The sensors are used to tell the PCME what the oxygen content in the exhaust stream is with respect to the ambient. From this, the PCME makes corrections to the injector pulse widths to maintain stoichiometry (i.e. about 14.7:1 air/fuel mixture). The sensors are used only when hot (they use heater elements to speed heat-up and reduce cold-start emissions) and when in “closed loop” mode (i.e. WOT is not closed loop).

A sensor will generally produce about 500mV output at stoich. When rich, the output voltage reaches a value above 500mV and when lean, the voltage falls below 500mV. The PCME tries to maintain 500mV average O2 sensor voltage so the averaged mixture is about 14.7:1.

The O2 sensors have 4-position connectors on them:

RHO2S Wire Colour LHO2S Wire Colour Purpose

R/BK R/BK Heater element supply from main relay

BK BK Heater element return (ground)

BK/Y DB/W Sensor output

BK/DB BK/DB Sensor return

Fault Description:

Inactivation errors 15 (left) & 23 (right) indicate the sensor never “woke up” from cold. Cold sensors produce little or no output voltage. Once the engine RPM exceeds 1500RPM, the PCME expects to see the voltage on the sensor(s) go above 500mV within 100 seconds. If it does not, the inactivation code gets set.

Inversion errors 17 (left) and 24 (right) occur when the sensor stops responding to the PCMEs adjustments to the A/F ratio. Inversion refers to the sensor swinging back and forth (or inverting) across 500mV as the PCME alternately makes the A/F ratio slightly richer or slightly leaner. If the sensor does not mirror theses changes, the PCME will set the inversion code.

PCME Fault Control Moding:

When any of codes 15, 17, 23 and 24 are set, the PCME falls out of closed loop mode and instead relies on calculations rather than feedback to control the A/F mixture. The effect will be lowered gas mileage, smelly exhaust, carbon accumulation etc.

Memorization:

This code is memorized in the PCME non-volatile memory.

Things To Check When Diagnosing:

The generally accepted solution for these errors is to replace the offending sensor, assuming no connector or wiring fault exists.

For codes 15 and 17, replace the left (radiator-side) O2 sensor. For codes 23 and 24, replace the right (firewall-side) O2 sensor.

Code 16: EGR Position Sensor

Sensor Purpose:

Exhaust Gas Re-circulation is used to re-route metered amounts of exhaust gases from the exhaust manifold (right side) to the intake tract. Doing this tends to reduce combustion temperatures and reduces the formation of smog- contributing oxides of nitrogen or “NOx”.

The PCME uses the EGR vacuum and vent solenoids in conjunction with the EGR position sensor to determine and modulate how much vacuum is applied to the EGR valve to regulate how much exhaust gas is entering the intake.

The EGR position sensor has a 3-position connector:

Wire Colour

Purpose

P +5V reference from the PCME

R/BK EGR position signal to PCME

BK/DB EGR sensor return (ground)

Fault Description:

Two conditions will result in a Code 16. The first condition is either a short or open condition where the sensor voltage reads below 0.196V or above 4.74V.

The second condition is where the EGR voltage is within the above specified parameters but the valve is not where the PCME thinks it should be. That is, if the sensor reads, say, 0.3V but the PCME is asking for 3.5V worth of EGR, Code 16 will get set.

PCME Fault Control Moding:

When Code 16 is present, zero EGR contribution is commanded. The result may be a proclivity to pinging (spark knock) and increased exhaust emissions.

Memorization:

This code is memorized in the PCME non-volatile memory.

Things To Check When Diagnosing:

Check the connectors and wiring between the PCME and the EGR position sensor.

Check the condition of the vacuum hoses and wiring at the EGR vent and vacuum solenoids. These solenoids are the release and apply solenoids – any malfunction in these may generate a Code 16.

Check the P wire for +5V with the ignition on. If Code 16 is accompanied by Codes 8 (VAF) or 12 (TPS) the PCME or wiring may be at fault.

Replace the EGR position sensor if all else checks out.

Codes 23 & 24: RHO2S Inactivation and/or Inversion

Sensor Purpose:

The oxygen sensors are located in the down-pipes in the exhaust manifolds. There are two sensors, one on each bank (California cars may use additional sensors). The radiator-side of the engine is known as the “left” side and codes 15 and 17 apply to it. The firewall side of the engine is known as the “right” side and codes 23 and 24 apply to it.

The sensors are used to tell the PCME what the oxygen content in the exhaust stream is with respect to the ambient. From this, the PCME makes corrections to the injector pulse widths to maintain stoichiometry (i.e. about 14.7:1 air/fuel mixture). The sensors are used only when hot (they use heater elements to speed heat-up and reduce cold-start emissions) and when in “closed loop” mode (i.e. WOT is not closed loop).

A sensor will generally produce about 500mV output at stoich. When rich, the output voltage reaches a value above 500mV and when lean, the voltage falls below 500mV. The PCME tries to maintain 500mV average O2 sensor voltage so the averaged mixture is about 14.7:1.

The O2 sensors have 4-position connectors on them:

RHO2S Wire Color LHO2S Wire Color Purpose

R/BK R/BK Heater element supply from main relay

BK BK Heater element return (ground)

BK/Y DB/W Sensor output

BK/DB BK/DB Sensor return

Fault Description:

Inactivation errors 15 (left) & 23 (right) indicate the sensor never “woke up” from cold. Cold sensors produce little or no output voltage. Once the engine RPM exceeds 1500RPM, the PCME expects to see the voltage on the sensor(s) go above 500mV within 100 seconds. If it does not, the inactivation code gets set.

Inversion errors 17 (left) and 24 (right) occur when the sensor stops responding to the PCMEs adjustments to the A/F ratio. Inversion refers to the sensor swinging back and forth (or inverting) across 500mV as the PCME alternately makes the A/F ratio slightly richer or slightly leaner. If the sensor does not mirror theses changes, the PCME will set the inversion code.

PCME Fault Control Moding:

When any of codes 15, 17, 23 and 24 are set, the PCME falls out of closed loop mode and instead relies on calculations rather than feedback to control the A/F mixture. The effect will be lowered gas mileage, smelly exhaust, carbon accumulation etc.

Memorization:

This code is memorized in the PCME non-volatile memory.

Things To Check When Diagnosing:

The generally accepted solution for these errors is to replace the offending sensor, assuming no connector or wiring fault exists.

For codes 15 and 17, replace the left (radiator-side) O2 sensor. For codes 23 and 24, replace the right (firewall-side) O2 sensor.

Code 25: FPRC Solenoid

Solenoid Purpose:

The FPRC or Fuel Pressure Regulator Solenoid is designed to vent the fuel pressure regulator to the atmosphere to bump fuel pressure slightly during hot start conditions. This increase in fuel pressure helps prevent fuel percolation and possible vapour-lock occurrences and helps stabilize the idle quality.

The FPRC is activated only when the coolant is above 70oC and the IAT is above 75oC. It remains active for 120-seconds or until the engine speed exceeds 1500RPM or the TPS is cracked slightly.

The FPRC solenoid sensor has a 2-position connector:

Wire Color

Purpose

DG/BK

FPRC control (PCME grounds to activate)

R/BK

+12V main relay power

Fault Description:

The FPRC solenoid is checked within the first 3-seconds of engine start-up or when the TEN pin is grounded. The PCME releases all solenoid control and then activates the FPRC solenoid. If solenoid is absent (i.e. the solenoid is not sensed to become active), the PCME detects this and sets code 25. If any solenoid is shorted to +12V, the PCME may be unable to detect any other solenoid failure.

PCME Fault Control Moding:

The PCME takes no remedial action if Code 25 is present.

Memorization:

This code is not memorized in the PCME non-volatile memory. When the engine is shut off, the code is not retained.

Things To Check When Diagnosing:

Check the connectors and wiring between the PCME and the FPRC solenoid.

Check for +12V at the R/BK wire of the connector. If absent, check the main relay and wiring.

Check the resistance of the solenoid. Typically it should be between 12-16 ohms at 20oC.

Code 26: Purge Control Solenoid

Solenoid Purpose:

The purge solenoid is designed to allow the vapor canister to be drained of “fumes” during optimal times to do so. When certain running conditions are met, the PCME activates the solenoid to literally vacuum fumes from the canister into the engine where they are burned. This reduces the emission of unburned hydrocarbons into the atmosphere.

The purge solenoid sensor has a 2-position connector:

Wire Color

Purpose

R/DB

purge control (PCME grounds to activate)

R/BK

+12V main relay power

Fault Description:

The purge solenoid is checked within the first 3-seconds of engine start-up or when the TEN pin is grounded. The PCME releases all solenoid control and then activates the purge solenoid. If solenoid is absent (i.e. the solenoid is not sensed to become active), the PCME detects this and sets code 26. If any solenoid is shorted to +12V, the PCME may be unable to detect any other solenoid failure.

PCME Fault Control Moding:

The PCME takes no remedial action if Code 26 is present.

Memorization:

This code is not memorized in the PCME non-volatile memory. When the engine is shut off, the code is not retained.

Things To Check When Diagnosing:

Check the connectors and wiring between the PCME and the FPRC solenoid.

Check for +12V at the R/BK wire of the connector. If absent, check the main relay and wiring.

Check the resistance of the solenoid. Typically it should be between 12-16 ohms at 20oC.

Code 28: EGR Vacuum Solenoid

Solenoid Purpose:

The vacuum solenoid is what the PCME uses, in conjunction with the vent solenoid, to control the amount of vacuum applied to the EGR valve diaphragm and thus its position

The vent solenoid sensor has a 2-position connector:

Wire Color Purpose

DG/W vacuum control (PCME grounds to activate)

R/BK +12V main relay power

Fault Description:

The vacuum solenoid is checked within the first 3-seconds of engine start-up or when the TEN pin is grounded. The PCME releases all solenoid control and then activates the vacuum solenoid. If solenoid is absent (i.e. the solenoid is not sensed to become active), the PCME detects this and sets code 28. If any solenoid is shorted to +12V, the PCME may be unable to detect any other solenoid failure.

PCME Fault Control Moding:

The PCME takes no remedial action if the Code 28 is present.

Memorization:

This code is not memorized in the PCME non-volatile memory. When the engine is shut off, the code is not retained.

Things To Check When Diagnosing:

Check the connectors and wiring between the PCME and the EGR vacuum solenoid.

Check for +12V at the R/BK wire of the connector. If absent, check the main relay and wiring.

Check the resistance of the solenoid. Typically it should be between 12-16 ohms at 20oC.

Code 29: EGR Vent Solenoid

Solenoid Purpose:

The vent solenoid is what the PCME uses, in conjunction with the vacuum solenoid, to control the amount of vacuum applied to the EGR valve diaphragm and thus its position

The vent solenoid sensor has a 2-position connector:

Wire Color Purpose

W/DB vent control (PCME grounds to activate)

R/BK +12V main relay power

Fault Description:

The vent solenoid is checked within the first 3-seconds of engine start-up or when the TEN pin is grounded. The PCME releases all solenoid control and then activates the vent solenoid. If solenoid is absent (i.e. the solenoid is not sensed to become active), the PCME detects this and sets code 29. If any solenoid is shorted to +12V, the PCME may be unable to detect any other solenoid failure.

PCME Fault Control Moding:

The PCME takes no remedial action if the Code 29 is present.

Memorization:

This code is not memorized in the PCME non-volatile memory. When the engine is shut off, the code is not retained.

Things To Check When Diagnosing:

Check the connectors and wiring between the PCME and the EGR vent solenoid.

Check for +12V at the R/BK wire of the connector. If absent, check the main relay and wiring.

Check the resistance of the solenoid. Typically it should be between 12-16 ohms at 20oC.

Code 34: Idle Air Control Solenoid

Solenoid Purpose:

The Idle Air Control (IAC) solenoid is modulated by the PCME to control the amount of air bypassing the closed throttle plate thus controlling the idle speed.

The IAC solenoid sensor has a 2-position connector:

Wire Color Purpose

LG/BK IAC control (PCME)

R/BK +12V main relay power

Fault Description:

The IAC solenoid is checked within the first 3-seconds of engine start-up or when the TEN pin is grounded. The PCME releases all solenoid control, exits closed-loop IAC control and then activates the IAC solenoid. If solenoid is absent (i.e. the solenoid is not sensed to become active), the PCME detects this and sets code 34. If any solenoid is shorted to +12V, the PCME may be unable to detect any other solenoid failure.

PCME Fault Control Moding:

The PCME exits IAC closed loop mode if Code 34 is present. This means the idle may be unstable, high or low.

Memorization:

This code is not memorized in the PCME non-volatile memory. When the engine is shut off, the code is not retained.

Things To Check When Diagnosing:

Check the connectors and wiring between the PCME and the IAC solenoid.

Check for +12V at the R/BK wire of the connector. If absent, check the main relay and wiring.

Check the resistance of the solenoid. Typically it should be between 12-16 ohms at 20oC.

Code 41: VRIS #1 Control Solenoid

Solenoid Purpose:

The VRIS valves are manifold-effective-length altering butterfly valves that are used to tune the length of the intake tract to maximize ram-effect tuning and thus torque. The PCME activates these valves at present RPM values if the TPS setting is high enough.

There are two valves. The #1 set is located the the left side (viewed from the radiator) and the #2 set is located nearer the throttle body. The solenoid for both valves are located at the firewall side of the intake plenum and you can see them just poking out from behind it. The #1 solenoid is the one on the left as viewed from the radiator.

The VRIS #1 solenoid sensor has a 2-position connector:

Wire Color Purpose

W/DG VRIS #1 control (PCME grounds to activate)

R/BK +12V main relay power

Fault Description:

The VRIS #1 solenoid is checked within the first 3-seconds of engine start-up or when the TEN pin is grounded. The PCME releases all solenoid control and then activates the #1 solenoid. If solenoid is absent (i.e. the solenoid is not sensed to become active), the PCME detects this and sets code 41. If any solenoid is shorted to +12V, the PCME may be unable to detect any other solenoid failure.

PCME Fault Control Moding:

The PCME takes no action when Code 41 is present. Power reduction at 3250 RPM will be noticed though.

Memorization:

This code is not memorized in the PCME non-volatile memory. When the engine is shut off, the code is not retained.

Things To Check When Diagnosing:

Check the connectors and wiring between the PCME and the VRIS solenoid.

Check for +12V at the R/BK wire of the connector. If absent, check the main relay and wiring.

Check the resistance of the solenoid. Typically it should be between 12-16 ohms at 20oC.

Code 46: VRIS #2 Control Solenoid

Solenoid Purpose:

The VRIS valves are manifold-effective-length altering butterfly valves that are used to tune the length of the intake tract to maximize ram-effect tuning and thus torque. The PCME activates these valves at present RPM values if the TPS setting is high enough.

There are two valves. The #1 set is located the the left side (viewed from the radiator) and the #2 set is located nearer the throttle body. The solenoid for both valves are located at the firewall side of the intake plenum and you can see them just poking out from behind it. The #2 solenoid is the one on the right as viewed from the radiator.

The VRIS #2 solenoid sensor has a 2-position connector:

Wire Color Purpose

DB/R VRIS #2 control (PCME grounds to activate)

R/BK +12V main relay power

Fault Description:

The VRIS #2 solenoid is checked within the first 3-seconds of engine start-up or when the TEN pin is grounded. The PCME releases all solenoid control and then activates the #2 solenoid. If solenoid is absent (i.e. the solenoid is not sensed to become active), the PCME detects this and sets code 46. If any solenoid is shorted to +12V, the PCME may be unable to detect any other solenoid failure.

PCME Fault Control Moding:

The PCME takes no action when Code 46 is present. Power reduction at 4250 RPM will be noticed though.

Memorization:

This code is not memorized in the PCME non-volatile memory. When the engine is shut off, the code is not retained.

Things To Check When Diagnosing:

Check the connectors and wiring between the PCME and the #2 VRIS solenoid.

Check for +12V at the R/BK wire of the connector. If absent, check the main relay and wiring.

Check the resistance of the solenoid. Typically it should be between 12-16 ohms at 20oC.

Code 67: LFAN Relay

Relay Purpose:

The LFAN (low-speed cooling fan) relay is used by the PCM to switch the large currents for the low-speed cooling fan.

Fault Description:

The LFAN relay is checked within the first 3-seconds of engine start-up or when the TEN pin is grounded. The PCME releases all solenoid and fan relay control and then activates the LFAN relay momentarily. If relay is absent (i.e. the solenoid is not sensed to become active), the PCME detects this and sets code 67. If any solenoid or relay is shorted to +12V, the PCME may be unable to detect any other solenoid failure.

NOTE: This code is present on 1993 model year PGTs and V6 MX6s only. Model years 1994 & 1995 will not report this code.

PCME Fault Control Moding:

The PCME takes no remedial action when Code 67 is present. The low-speed fan may not operate and overheating is possible.

Memorization:

This code is not memorized in the PCME non-volatile memory. When the engine is shut off, the code is not retained.

Things To Check When Diagnosing:

Check the LFAN relay socket and the relay pins for corrosion.

Replace the relay if necessary.

Code 69: ECTF Sensor

Sensor Purpose:

The ECTF (engine coolant temperature – fan) sensor is used by the PCM in 1993 models to determine when it is necessary to turn on the radiator cooling fans. In 1994, the ECT (see code 9) was used to make the same determination, saving the expense of one sensor and its wiring.

Fault Description:

The PCM will set a code 69 if the voltage on the ECTF sensor circuit falls below 1.15V or rises above 4.98V.

NOTE: This code and sensor is present on 1993 model year PGTs and V6 MX6s only. Model years 1994 & 1995 will not report this code.

PCME Fault Control Moding:

To safeguard against overheating, the PCME will activate the cooling fan constantly when code 69 is present.

Memorization:

This code is memorized in the PCME non-volatile memory.

Things To Check When Diagnosing:

Check the sensor plug. Make sure there’s no corrosion and that the wiring is in good shape.

Use the table for code 9 and check the resistance of the sensor. They should be similar.

Replace the sensor if necessary.