Adjustable Timing Belt Tensioner

Selling fast! Over 19 people have in their cart

Don’t get stranded from a common failure, use our tensioner for reliability!

- Fitment Guaranteed

- Fast Shipping

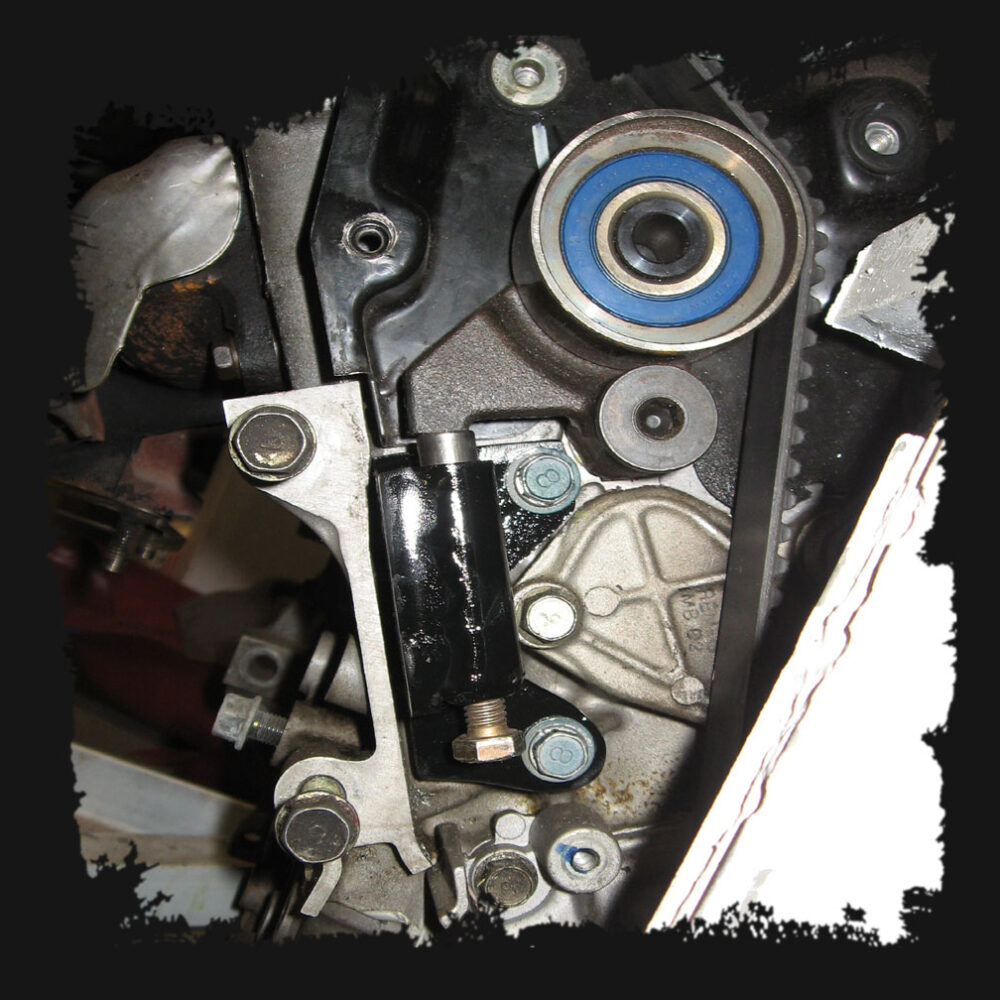

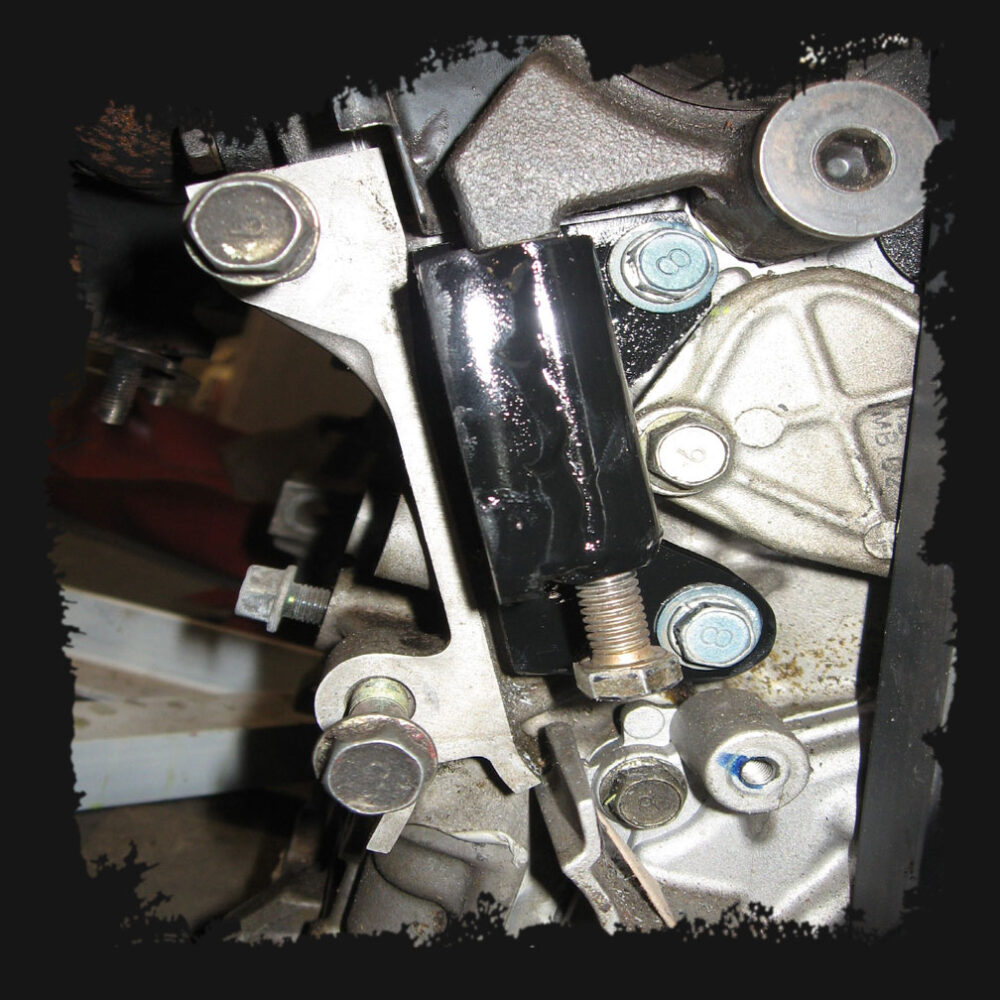

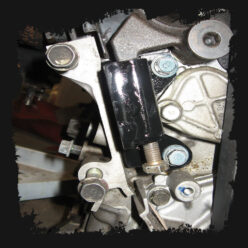

Our Manual Timing Belt Tensioner is designed to replace the OEM Auto hydraulic tensioner that is a common to failure point on the KL series engine. When the OEM auto tensioner fails it allows the timing belt to jump on the valve train causing a no start or retarded timing condition.

Features:

- New Design allows precise adjustments

- New Design can be adjusted easily with flex head 3/8 ratcheting wrench

- This tensioner is a direct replacement on the KL V6 engines.

- No modifications needed to the engine.

- Painted in POR15 Top Coat Gloss Black

Options:

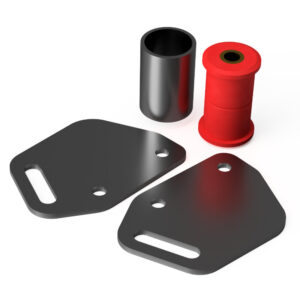

- With Hardware: Timing Tensioner will use the existing hardware from your OEM auto tensioner. This hardware may be too long and require washers to tighten the tensioner fully.

- Without Hardware: Timing Tensioner includes (2) 8mm x 14mm High-Strength Steel Flanged Hex Head Screw’s that are sized correctly to tighten tensioner fully.

Suggestions:

- Part of the timing belt cover can be cut away for future adjustments if needed (pictured) or leave the covers off entirely.

- If removing the covers entirely, see our timing mark bracket to retain the ability to properly set the timing.

| Design | Made to Order |

|---|---|

| Engine | KLDE, KLG4, KLZE |

| Model Year | 1993, 1994, 1995, 1996, 1997 |

| Vehicle | Ford Probe, Mazda 626, Mazda Mx3, Mazda Mx6 |

| Category Type | Engine |

| Location | Engine |

| Product Category | Mazda GE Platform |

| Style Rating | Elite |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.