Showing all 6 results

-

1995+ Cam Sensor Retrofit

0 out of 5$40Original price was: $40.$35Current price is: $35.Are you looking to convert a distributor to Cam Sensor only?

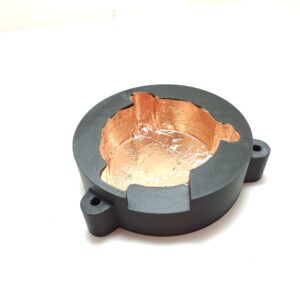

Our solution removes unneeded parts of the distributor and finishes it off with clean appearance. The parts are 3D printed in Black ABS-Glass Fiber with 6 walls and 35% Infill for strength and heat resistance.

What’s included in this product:

- (1) Outer Large Cap with Shielding on inside

- (2) Inner filler cap.

Fitment:

This for a 95-97 Year KLDE distributor, Filing could be needed for odd brand distributor’s.

This product is for the retrofit parts to convert a 1995-1997 distributor to use a cam sensor only. This requires removal of the internal coil and igniter from the distributor. These parts reuse the existing screws from the distributor.

These Retrofit parts are documented on our information page here.

With these parts, your distributor will look like this: ( Distributor not included in this item)

-

Timing Mark Bracket

$45 – $60Price range: $45 through $600 out of 5Our Timing Mark Bracket is designed specifically to fit on the KLDE V6 engine. It allows you to run your engine without the timing belt covers and still time the engine accurately.!

The timing mark bracket bolts onto the engine block using existing holes from the OEM timing belt cover and allow clearance for the timing belt system.

Features:

- The bracket is designed to be used without timing belt cover.

- Can be used with OEM KLDE 6-1 crank pully or KLG6 42-1 crank pully

- 3D Printed In ABS-Glass Fiber with ASA colors to withstand heat and elements

- Is imprinted with the same timing reference as the stock covers and utilizes factory mount holes.

- Rated up to 350F, Ozone and chemical resistant.

Product includes:

- (1) 3D Printed Timing Mark Bracket with choice of color layout.

- (2) M6 Socket head mounting screws

Select options This product has multiple variants. The options may be chosen on the product page -

12 Pin Pigtail Connector w/6″ Leads

$100 out of 5Pigtail Pulled from 93 Mx6 V6 with Manual Transmission

Pigtail Connector Type: KLDE Main Engine Harness Interconnect

-

KLDE Throttle Cable

$300 out of 5

Used Parts Removed From:

Removed from a 1994 Mx6 with KLDE Engine

Used Parts Condition:

Good

All Used parts are sold “as is” in the stated and pictured condition. No warranty, No Returns accepted.

End of content

End of content