Polyurethane Rear Motor Mount

The Factory rear motor mount is the most common mount to wear out first.

- Fitment Guaranteed

- Fast Shipping

Why upgrade motor mounts?”

Factory motor mounts are made of a soft rubber to control vibration and interior noise during normal driving. This soft rubber reduces overall torque to the wheels because some of the engine torque is absorbed into the soft mount. This torquing motion into the mount can also destroy the mount and allow excessive movement that can ruin transmission cases and cause wheel hop. Most commonly, the front and rear motor mounts take the brunt of the torquing motion and wear out the quickest.

Upgrade to Polyurethane

These motor mounts feature 88 durometer Prothane Polyurethane bushings. The polyurethane bushings help eliminate chatter, engine rotation, wheel hop and missed shifts that can result in broken parts associated with drive line flex. Additionally, these polyurethane bushings are ozone resistant, chemical resistant and will not rot like rubber. They are also very durable, and easy to replace if they ever become wore out. Every mount is CNC cut, machine bent and MIG welded on a JIG for a ensured correct fit for your application.

Sleeve Size Option:

- Standard: The mount will include oversized 1/2″-13 Hardware. These oversized bolts will take up any slop that has worn into the engine support bracket over time, ensuring a maximum tight fit of all your engine mounts. This hardware includes: (Qty:1) 1/2″-13 Bolt, (Qty:1) 1/2″-13 Nylon locking nut, (Qty:2) 1/2″ washers.

- Metric: The mount will include a metric sleeve without hardware. This option requires you to utilize your existing OEM hardware from the factory motor mount. This sleeve is custom machined on a lathe to be metric size.

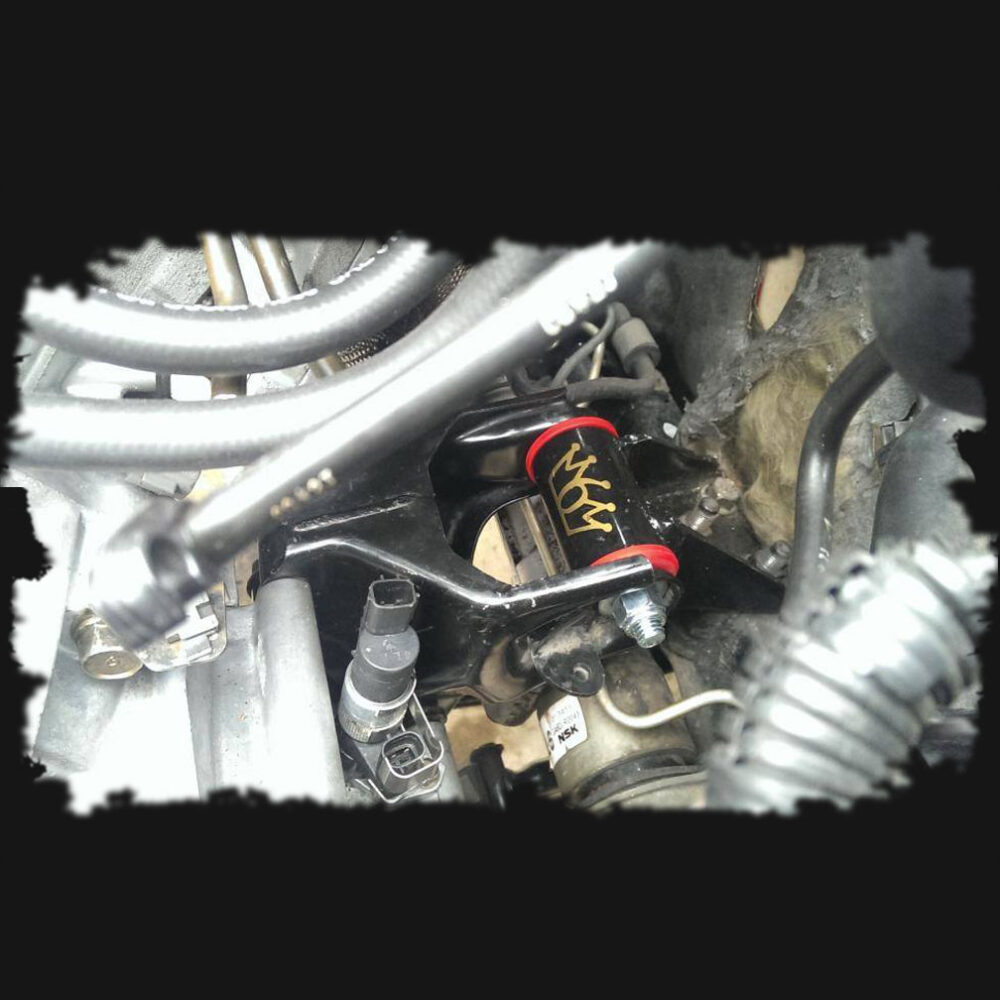

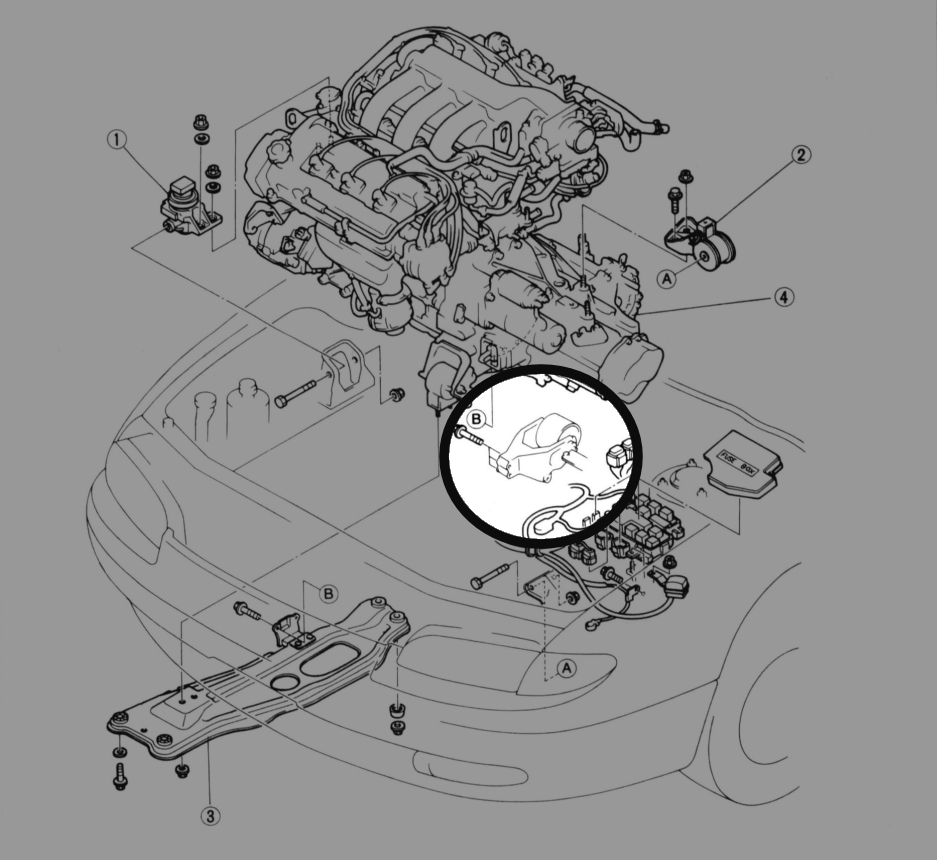

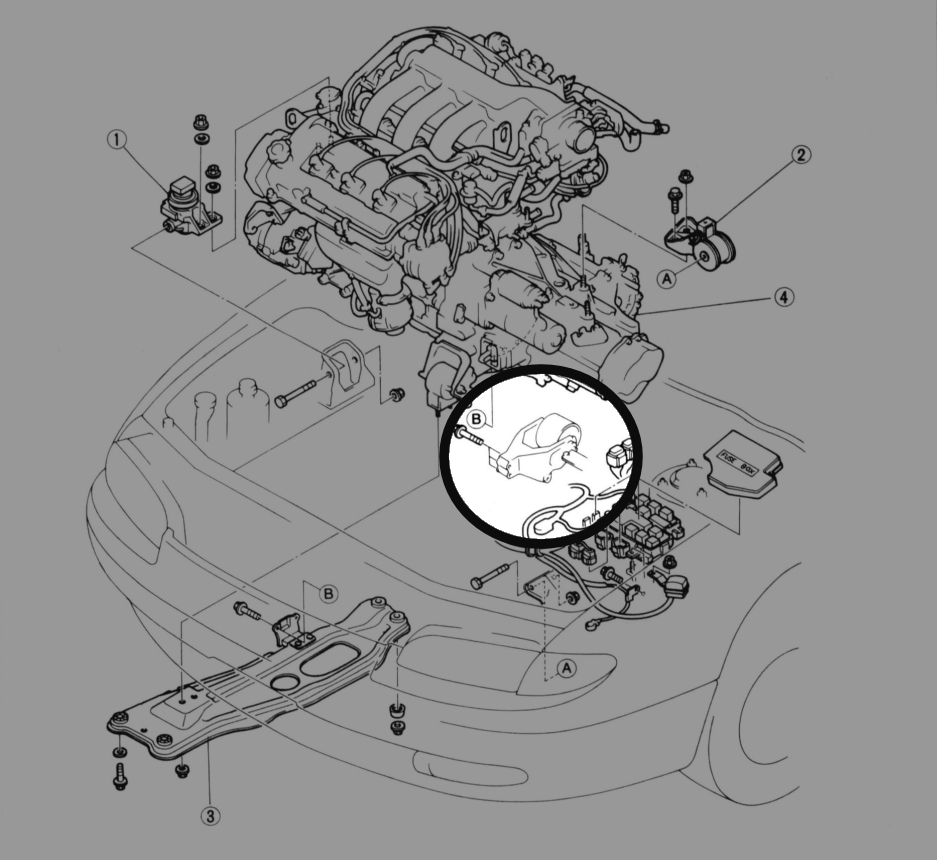

Location of this motor mount on your car:

This mounted on the passenger side of the engine compartment between the timing belt components and above the water pump. I connects to the chassis and direct the engine block.

| Bushing Color | Black, Random, Red |

|---|---|

| Design | Made to Order |

| Engine | KLDE, KLZE |

| Category Type | Drivetrain, Engine |

| Location | Engine |

| Product Category | Mazda GE Platform |

Only logged in customers who have purchased this product may leave a review.

Parts Fit the Following Vehicle’s:

1993-1997 Ford Probe V6 Models

1993-2001 Mazda 626 V6 Models

1993-1997 Mazda Mx6 V6 Models

Production vehicles are built using rubber bushings in control arms, strut arms, leaf springs, body mounts, motor mounts, transmission mounts, sway bars, and shocks. Additionally, rubber components can be used for: sway bar end links, coil spring pads, leaf spring pads, and suspension bump stops. While rubber components offer a soft side, for typical driving conditions, they tend to deteriorate rapidly from exposure to the elements and constant use! This contributes to premature component failure, resulting in a “spongy” ride and loss of performance handling. PROTHANE™ Urethane is impervious to the elements, gas, and oil, will not rot and is strongerthan rubber.

Production vehicles are built using rubber bushings in control arms, strut arms, leaf springs, body mounts, motor mounts, transmission mounts, sway bars, and shocks. Additionally, rubber components can be used for: sway bar end links, coil spring pads, leaf spring pads, and suspension bump stops. While rubber components offer a soft side, for typical driving conditions, they tend to deteriorate rapidly from exposure to the elements and constant use! This contributes to premature component failure, resulting in a “spongy” ride and loss of performance handling. PROTHANE™ Urethane is impervious to the elements, gas, and oil, will not rot and is strongerthan rubber.

Reviews

There are no reviews yet.