I planned this Bending machine around a JD2 Model 32 bender. My goal was to design something that allowed mobility of the machine to be moved to odd jobs as I needed. While containing the Dies and tooling inside the machine so that they could be locked up to keep unwanted users from messing with it.

Also, I work in a shop that is subject to inspection by OSHA & Insurance companies so I need this machine to be safety compliant as possible.

Equipment and Parts Initially Purchased

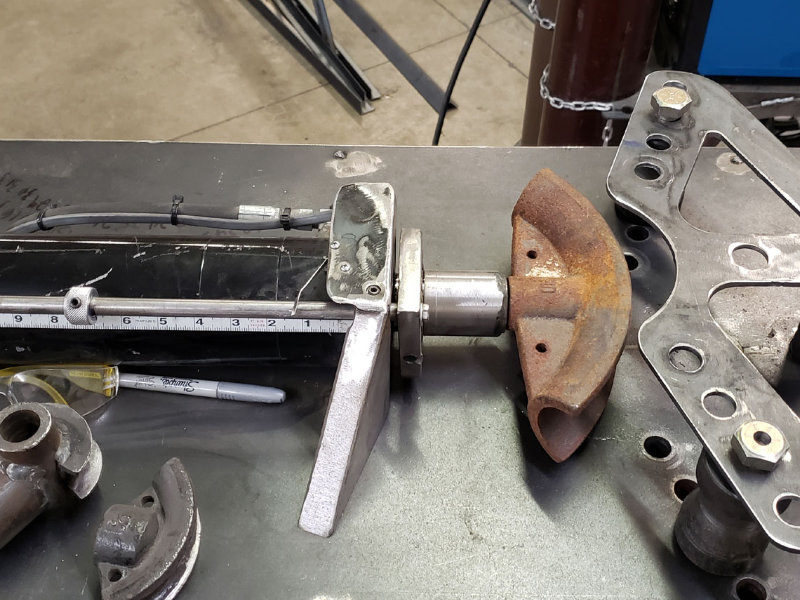

- JD2 Model 32 Manual Bender

- Double Acting Hydraulic Pump for Dump Trailers KTI – 12 VDC – 6 Quart Reservoir

- HYDROWORKS Double Acting Welded Hydraulic Cylinder 3″ Bore 24″ Stroke, 3000 PSI

I started this project with the idea in mind that I wanted it to be on a rolling cart, that could be self contained and the ability to be locked to prevent unwanted operation.