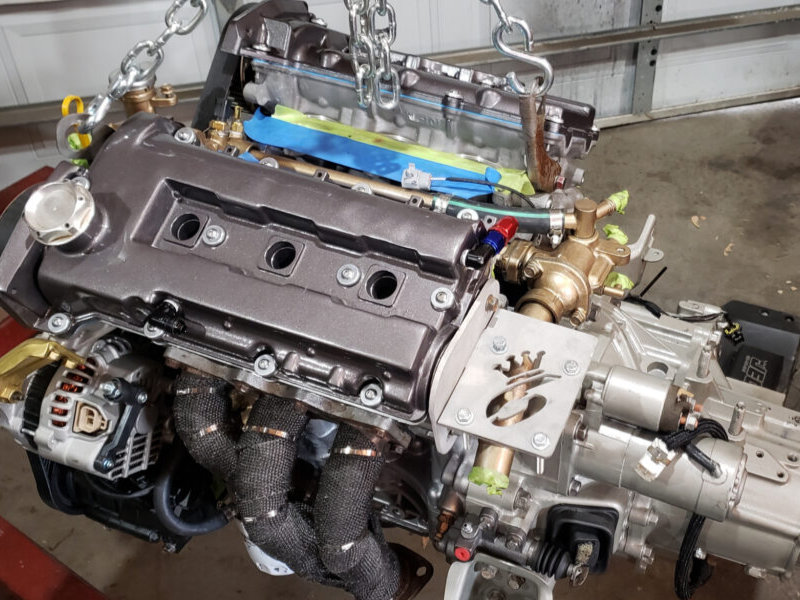

Camshafts

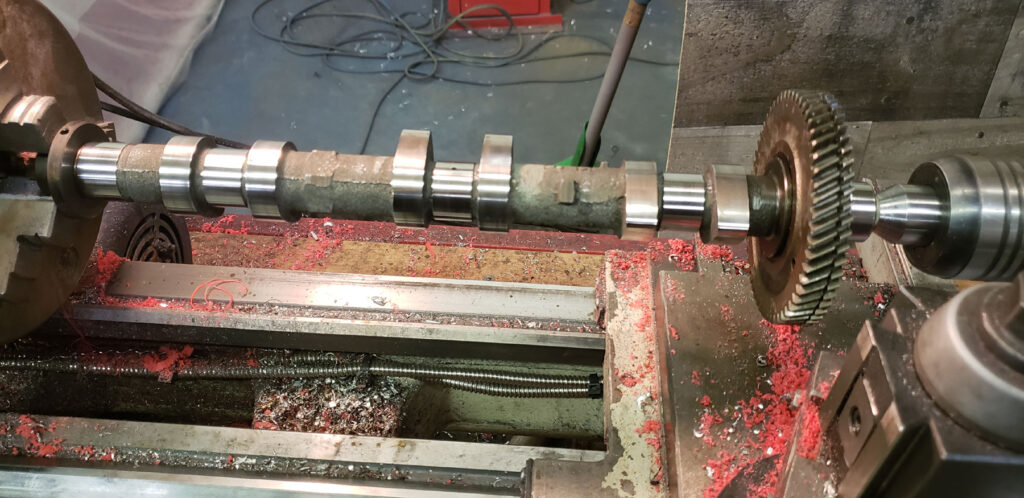

It turned out that after years of the spare engine sitting in a garage thru all seasons, winter being the harshest.. the cams had developed some surface rust on them. I first put them in a engine de-greaser for about 4hours,this ate all the surface rust from and burned oil off the non machined part of the camshafts, but still left surface rust on the lobes.

I was able to place them in the lathe and put them on a 500rpm spin. Starting with some 220grit sand paper I cleaned them and polished them up during a process from 220grit to 400grit, to 800grit, to 1000grit, finally to 1500grit. This was challenging to do by hand being the lobes jolt your hand. I found it best to use emery cloth type sand paper and band it around the journal in the opposite direction the lathe is turning.

After completing all 4 camshafts, I used a blow gun with carburetor nozzle attachments to blow out to oil ports for the cam journals.

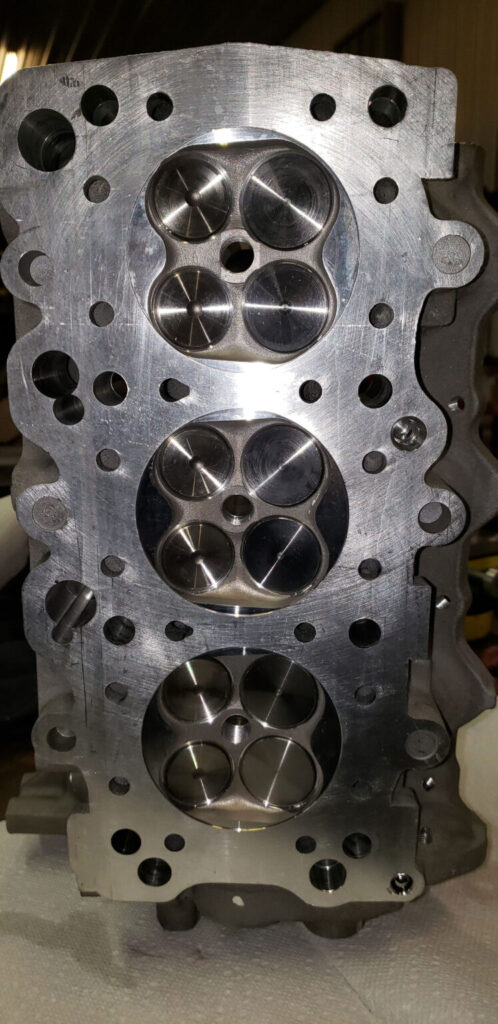

Valve Guide Seal Installation

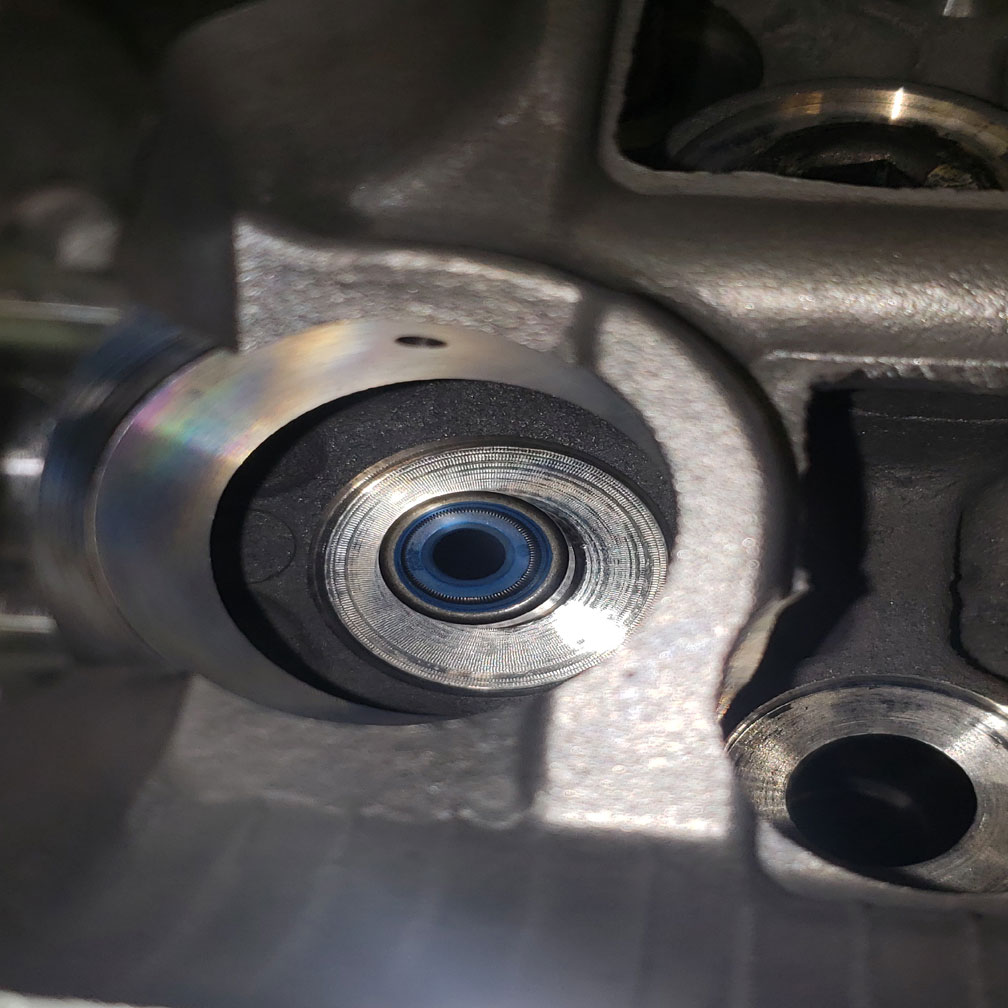

Removing the OEM style valve seals is an easy job, a long flat nose pliers works well to pull them off easily.

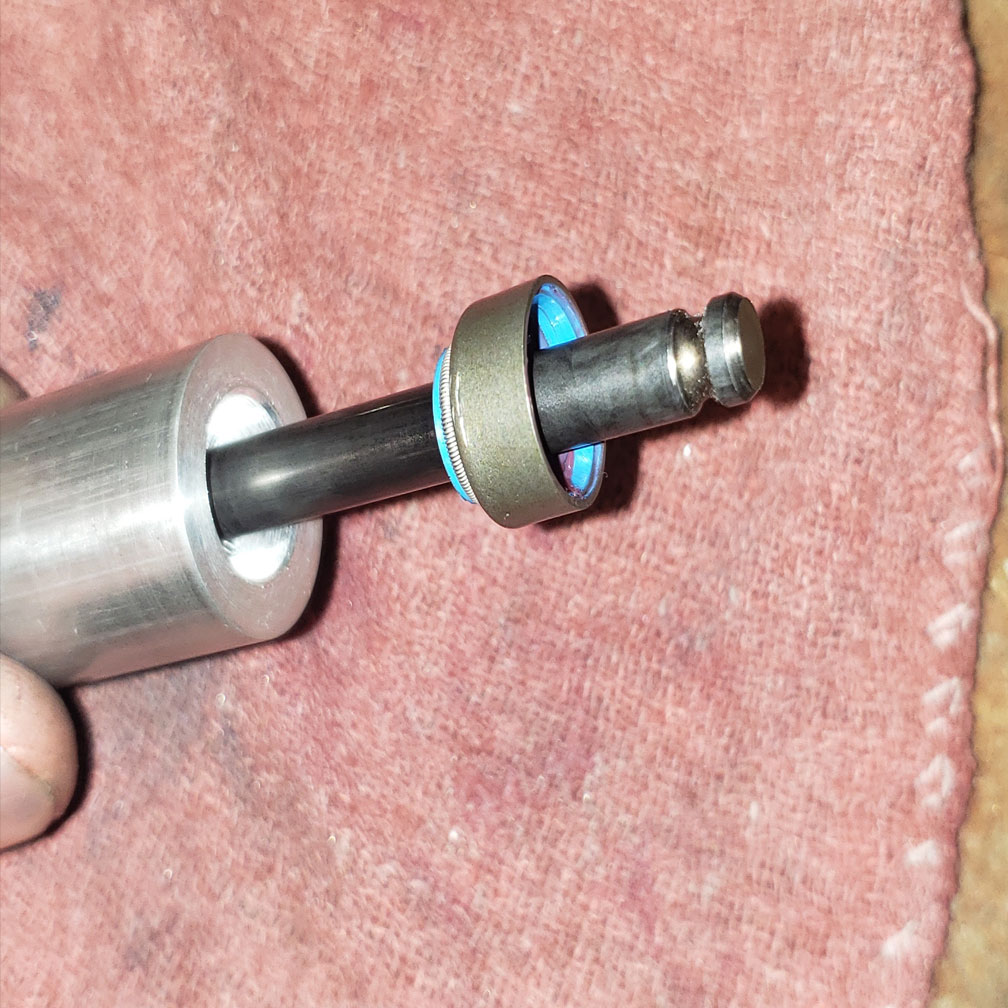

Installing valve seals is another story, simply pushing them on by hand and tapping with an object is certain to damage the seal. The cheap seal installer tools you can buy on Ebay and Amazon don’t fit well and can also damage the seals. So I came up with a simple design using a old exhaust valve from the old cylinder heads. I machined out a bushing to hold the seal and slide onto the valve. This allows the valve to be inserted into the valve guide and the seal can be installed perfectly.

Valves Installation

Intake and Exhaust

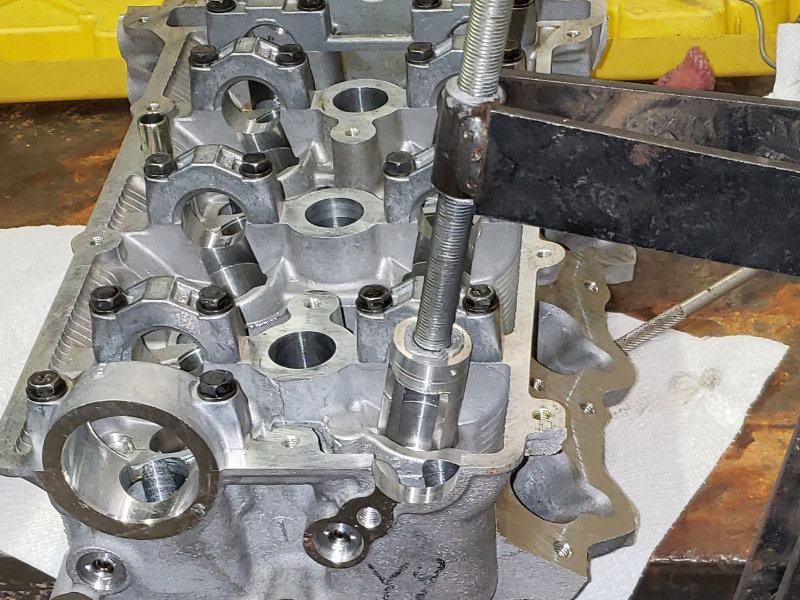

Installing the new intake and exhaust valves proved another challenge. I bought the most common C clamp type valve spring compressor found on Ebay & Amazon. The tool appeared to be decent quality for the price of it but I quickly found out appearance was all that was decent about it. The valve spring compressor could not compress the springs, instead the compressor bent outward, to an amount that it couldn’t be put back in the cast without bending it back. Bending it back was easily done by hand.

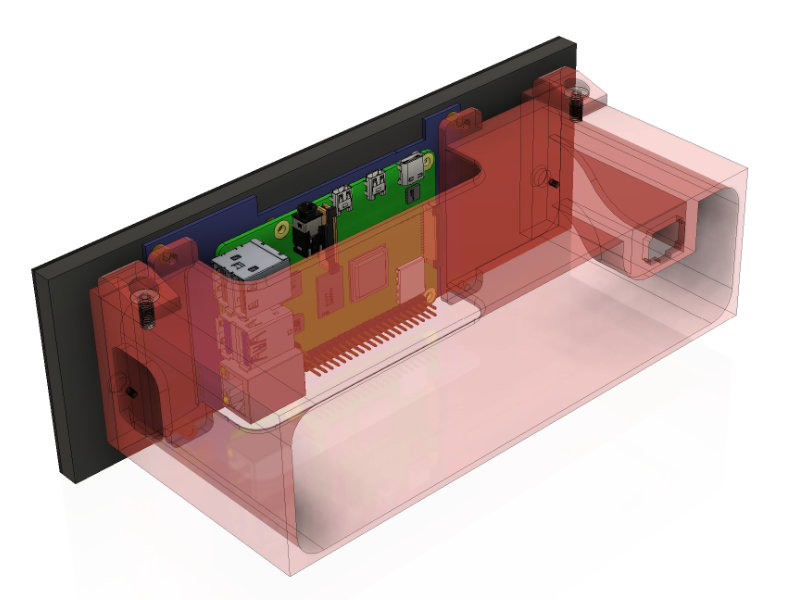

Again I was back to designing something to complete this job. I quickly drew up a cut file and cut it out on the Plasma CNC, made and welded in some threaded inserts. I now have a valve spring compressor for any job.

Its recommended to apply a light coat of engine oil to the valve while inserting. The valve keepers are very challenging to get back into place, I found the best way is to compress the valve spring so the valve keeper retainer just pushes past the notch in the valve. Place both keepers with a small pick or pliers while slowly releasing pressure on the valve spring.