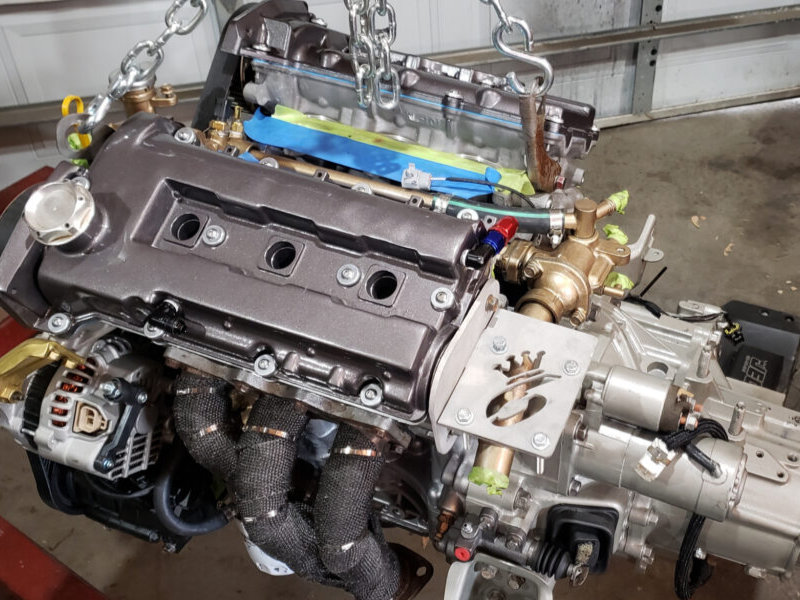

First order of business was to disassemble the engine down to the bare block and get it to the machine shop.

I did not photo any of this progress because it seemed straight forward and nothing impressive.

Not having much faith in my own judgment of accuracy I decided to bring the crank shaft into get inspected and possibly ground if needed. It turned out my crank was in perfect shape and I asked them to polish it while they had it.

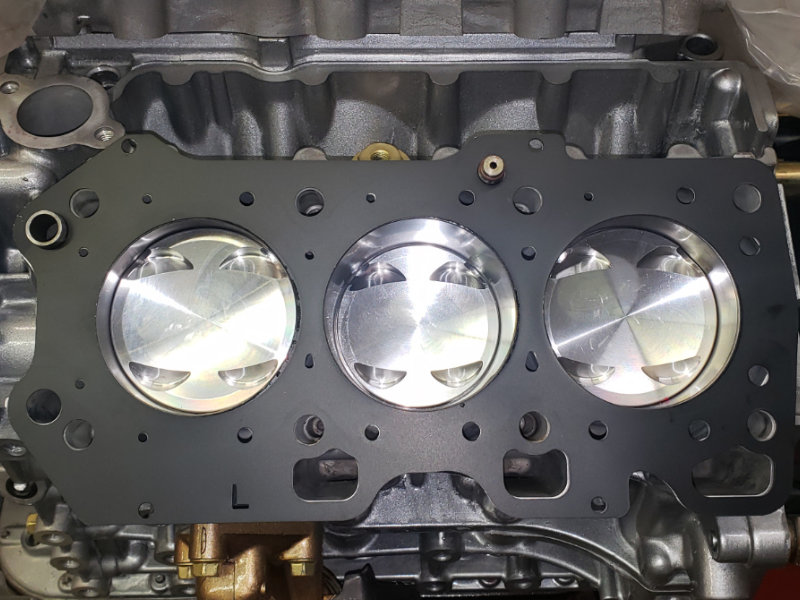

A note for when bringing in your engine block to a machine shop, make sure to include the bottom girdle of the block and all the bolts that secure it to the block. They need this to mount the block properly in their machines. My machine shop also wouldn’t bore the block without the pistons physically in hand to test fit.

When I received my block back completed, it had been chemically cleaned and turned out excellent. They however didn't clean mating surfaces of any part of the block such as for the head, oil filter housing, oil pan, water pump or oil pump.

Sine It was up to me to do this I used a air grinder set on low with buffer wheel using medium grit scotch brite quick lock disc. This cleaned up the surfaces perfectly. I then washed the engine block with a non chlorinated brake cleaner, blew it off with compressed air, and repeated this cleaning process multiple times.

While storing the block during the process of building, I lubed the cylinders with the redline assembly oil and covered the block with 2 industrial type plastic bags.